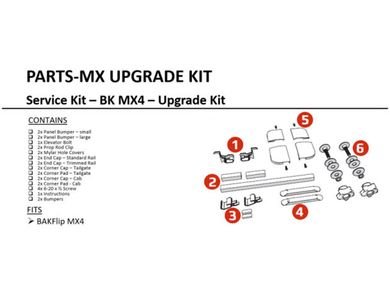

BAKFlip Corner Cap & End Cap Replacement Guide

BAKFlip MX4 Corner Cap Replacement Kit

Part BAK-351S0002 includes four genuine high-impact ABS corner caps designed specifically for MX4 tonneau covers. These weather-resistant corner caps protect panel edges from cargo damage while maintaining precise weatherproof sealing. Engineered to withstand temperature extremes from -40°F to 180°F without cracking or warping. Installation takes just 10 minutes with simple snap-on design requiring no tools or drilling. Compatible with all BAKFlip MX4 models across Ford F-150, Chevy Silverado, RAM 1500, and Toyota Tundra applications.

BAKFlip MX4 End Cap Assembly

Part BAK-356A0012 features integrated drainage channels and reinforced mounting points for superior durability. These end caps direct water away from cargo while providing structural support to panel edges during folding operations. Premium UV-resistant material maintains color and flexibility through years of sun exposure. Precision-molded design ensures exact fit without gaps that compromise weather sealing. Essential replacement component when original caps show cracking, color fade, or loose attachment. Compatible with all MX4 truck bed lengths.

BAKFlip Corner Cap Installation Kit

Complete installation kit includes replacement corner caps plus all necessary mounting hardware and installation tools. Features step-by-step instructions with detailed photos showing proper alignment and attachment procedures. Includes adhesive promoter and cleaning supplies for maximum bond strength on various truck bed rail materials. Professional-grade components ensure long-lasting attachment that won’t fail during extreme weather or heavy use. Perfect for DIY installation or professional technicians servicing multiple covers.

BAKFlip G2 Corner Cap Upgrade Kit

Enhanced G2-style corner caps retrofit to MX4 covers providing improved impact resistance and refined appearance. Features reinforced mounting tabs and upgraded polymer construction for extended service life. These premium corner caps include improved drainage design and enhanced UV protection compared to standard MX4 caps. Installation requires removing original caps and following specific alignment procedures. Popular upgrade for MX4 owners seeking maximum durability and enhanced appearance for their tonneau cover system.

Understanding BAKFlip Corner Cap Function

The BAKFlip corner cap serves multiple critical functions beyond simple appearance enhancement. These precision-engineered components protect vulnerable panel corners from cargo impacts while maintaining structural integrity during thousands of folding cycles. Most truck owners underestimate how much stress these small components endure daily.

Corner caps absorb impact energy when cargo shifts during transport, preventing damage to expensive aluminum panels beneath. Without proper corner protection, boxes, tools, and equipment create stress concentrations that lead to panel cracking and premature failure. Quality corner caps distribute impact forces across wider areas, preserving panel integrity.

These components also maintain weatherproof sealing between panels and truck bed rails. Damaged or missing corner caps create gaps where water, dust, and debris enter your cargo area. The precision-molded design ensures consistent compression against sealing surfaces, maintaining protection even after years of temperature cycling and UV exposure.

The drainage function built into genuine BAKFlip MX4 corner caps directs water away from critical areas. Small channels molded into cap surfaces guide moisture toward drain holes rather than allowing pooling that leads to corrosion. This engineering detail separates genuine parts from generic alternatives that lack proper drainage design.

Common Corner Cap Failure Modes

Understanding how corner caps fail helps identify replacement timing before problems affect cover operation. Impact cracking represents the most common failure mode, especially in work trucks carrying heavy tools or equipment. Hairline cracks spread quickly under repeated stress, eventually causing complete cap separation.

UV degradation causes another frequent failure pattern. Prolonged sun exposure breaks down plastic polymers, making caps brittle and prone to cracking. Color fading indicates UV damage beginning—replace caps showing significant color change before brittleness develops. Southern climates experience faster degradation than northern regions.

Adhesive failure creates loose caps that rattle during driving and compromise weather sealing. Temperature cycling expands and contracts materials at different rates, stressing adhesive bonds. Poor surface preparation during installation accelerates adhesive failure. Loose corner caps require immediate replacement to prevent complete detachment and potential loss.

Chemical damage from harsh cleaners, road salt, or industrial exposure degrades cap materials and finishes. Truck owners using strong degreasers or pressure washing with commercial chemicals may notice surface deterioration and weakened material. Choose cleaning products specifically formulated for automotive plastics to prevent chemical damage.

BAKFlip MX4 Corner Cap Replacement Process

Replacing BAKFlip MX4 corner caps requires minimal tools and mechanical skill, making it an ideal DIY maintenance task. The entire process takes 15-30 minutes depending on adhesive removal difficulty and surface preparation requirements.

Begin by opening your tonneau cover completely and securing panels in upright position. Clean the work area thoroughly, removing dirt and debris that could contaminate adhesive surfaces. Gather necessary tools—plastic pry tools, adhesive remover, cleaning supplies, and replacement caps—before starting removal procedures.

Removing damaged caps requires patience to avoid damaging surrounding surfaces. Start by gently prying one corner using plastic tools to avoid scratching aluminum panels. Work slowly around the cap perimeter, gradually releasing adhesive bonds. Avoid using metal tools that scratch or gouge expensive panel surfaces requiring costly refinishing.

Stubborn adhesive residue yields to commercial adhesive removers or careful heat application. Hair dryers soften adhesive for easier removal—avoid excessive heat that warps plastic components. Scrape residue with plastic scrapers, then clean surfaces with isopropyl alcohol for proper adhesion of replacement caps.

Surface Preparation Critical Steps

Proper surface preparation determines replacement cap longevity and adhesive strength. Contaminated surfaces cause premature failure regardless of genuine parts quality. Clean surfaces must be completely dry and free from oils, wax, or chemical residues before cap installation.

Inspect mounting surfaces for damage requiring repair before cap installation. Small scratches accept touch-up paint to prevent corrosion. Deeper gouges may need body filler for smooth surfaces. Address surface damage before installing new caps—adhesive won’t bridge significant gaps or irregularities.

Temperature affects adhesive performance significantly. Install caps in temperatures between 60-85°F for optimal bonding. Cold weather makes adhesives less tacky while excessive heat causes immediate setup before proper positioning. Garage installation provides temperature control and clean environment for best results.

Test-fit new caps before removing adhesive backing to verify proper alignment and fitment. Quality genuine BAKFlip corner caps fit precisely without forcing or trimming. Poor fit indicates wrong part numbers or counterfeit components. Genuine parts install smoothly with perfect alignment to existing features.

Installation Best Practices

Start installation at one corner and work systematically around the cap perimeter for even adhesive contact. Press firmly for 30 seconds at each point to ensure proper adhesive flow and surface contact. Avoid repositioning caps once adhesive contact occurs—repositioning weakens bonds and creates leak paths.

Apply steady, even pressure during installation rather than excessive force in small areas. Distribute pressure with clean rags or soft tools to avoid fingerprints on finished surfaces. Complete installation within adhesive working time—usually 5-10 minutes depending on temperature and humidity conditions.

Allow 24 hours curing time before subjecting caps to stress or moisture exposure. Premature loading can compromise adhesive bonds that haven’t reached full strength. Avoid operating the cover during initial curing period to prevent cap displacement or adhesive failure.

Inspect installation after curing period to verify proper bonding and alignment. Quality installations show no gaps, uniform surface contact, and smooth transitions to surrounding surfaces. Address any irregularities immediately rather than hoping problems resolve themselves over time.

End Cap Function and Replacement

BAKFlip MX4 end caps perform different functions than corner caps while sharing similar installation procedures. End caps seal the tailgate edge of your tonneau cover, preventing water intrusion and providing finished appearance. These components endure unique stresses from tailgate impacts and loading activities.

End caps include integrated drainage channels directing water away from tailgate seals and cargo areas. Blocked drainage causes water backup and potential leaks into covered cargo. Regular cleaning maintains proper water flow and prevents ice formation during winter months that can crack cap materials.

The structural role of end caps includes supporting panel edges during folding operations. Quality end caps maintain panel alignment and prevent binding during opening and closing cycles. Worn end caps allow panel misalignment that creates premature wear and difficult operation.

Replacement timing for end caps follows similar patterns to corner caps—impact damage, UV degradation, and adhesive failure represent primary failure modes. However, end caps experience different stress patterns from tailgate operation and cargo loading that may accelerate wear in specific areas.

End Cap Installation Differences

Installing BAKFlip MX4 end caps requires additional attention to drainage channel alignment and tailgate clearance. Proper alignment ensures water flows toward designated drain points rather than pooling against seals. Misaligned end caps create water retention and potential freeze damage.

Check tailgate clearance during end cap installation to prevent interference during tailgate operation. Some aftermarket tailgate accessories may require clearance modifications or spacers for proper end cap fitment. Test tailgate operation through full range of motion before finalizing installation.

End cap adhesive experiences different stress patterns than corner caps due to tailgate vibration and impact loading. Use high-strength automotive adhesives designed for dynamic applications rather than static mounting compounds. Follow manufacturer curing recommendations for maximum bond strength.

Genuine vs Aftermarket Corner Caps

The market floods truck owners with aftermarket BAKFlip corner cap alternatives promising significant cost savings. While initial purchase prices seem attractive, aftermarket caps rarely deliver genuine part performance or longevity. Understanding these differences prevents costly mistakes and repeated replacements.

Genuine BAKFlip corner caps undergo extensive testing for material durability, UV resistance, and temperature cycling. BAK Industries validates every component through real-world testing and accelerated aging procedures. Aftermarket manufacturers skip these expensive validation steps, resulting in premature failures under normal use conditions.

Material quality represents the biggest difference between genuine and aftermarket components. Genuine caps use high-impact ABS plastic specifically formulated for automotive applications. Aftermarket caps often substitute cheaper materials that crack easily, fade quickly, and degrade from common automotive chemicals.

Dimensional accuracy ensures proper fit and function with existing tonneau cover components. Genuine caps match original specifications exactly, maintaining weatherproof sealing and structural integrity. Aftermarket dimensional variations create gaps, interference problems, and compromised weather protection that defeats the tonneau cover’s primary function.

Cost Analysis: Genuine vs Aftermarket

Initial cost comparisons favor aftermarket caps by $20-40 per set. However, total cost of ownership calculations reveal genuine parts provide better value through extended service life and superior performance. Genuine caps lasting 6-8 years versus aftermarket caps requiring replacement every 2-3 years shifts cost advantage to genuine components.

Installation labor costs multiply when using short-lived aftermarket parts. Professional installation fees of $50-80 per replacement cycle add up quickly with frequent aftermarket failures. DIY installation time also multiplies—time spent on repeated replacements that could be avoided with genuine components.

Warranty implications create hidden costs with aftermarket parts. Using non-genuine components can void your BAKFlip tonneau cover warranty, potentially costing hundreds of dollars in denied claims for related failures. That $30 saved on cheap corner caps could cost $500 in voided warranty coverage.

Performance compromises from aftermarket parts include poor weather sealing, reduced impact protection, and aesthetic mismatches. Water damage to cargo from compromised weather sealing can exceed the cost of genuine parts many times over. Professional appearance matters for business truck owners where image affects customer perceptions.

Identifying Genuine Parts

Genuine BAKFlip corner caps include specific identification features that distinguish them from aftermarket alternatives. Look for BAK Industries part numbers molded into plastic components—genuine parts always include proper part number identification. Counterfeit parts often omit part numbers or use incorrect numbering schemes.

Packaging quality provides another identification method. Genuine parts arrive in professional BAK Industries packaging with detailed installation instructions and warranty information. Aftermarket parts often come in generic bags with minimal or poor-quality documentation.

Material quality becomes apparent during handling. Genuine caps feel substantial and well-made with smooth surfaces and precise molding. Aftermarket caps often feel lightweight with rough surfaces, visible molding defects, and poor finish quality. Trust your hands—quality differences are immediately apparent.

Color matching accuracy helps identify genuine components. BAK Industries maintains strict color standards ensuring replacement parts match original equipment exactly. Aftermarket parts often show color variations and inconsistent finishes that create obvious mismatches with existing components.

Maintenance Tips for Extended Cap Life

Proper maintenance extends BAKFlip corner cap service life significantly while maintaining optimal performance throughout their operational lifetime. Simple care procedures prevent premature failure and maintain the professional appearance that reflects well on your truck and business.

Monthly cleaning routines remove corrosive contaminants before they cause permanent damage. Use mild car wash soap and soft brushes to clean cap surfaces and drainage channels. Avoid harsh degreasers or industrial cleaners that degrade plastic materials and finishes. Rinse thoroughly and dry completely to prevent water spots and mineral deposits.

Quarterly inspections identify developing problems before they require emergency repairs. Check for hairline cracks, loose attachment, color fading, and drainage blockages during routine truck maintenance. Early detection allows planned replacement during convenient times rather than roadside emergencies.

Apply UV protectant products every six months to slow degradation from sun exposure. Quality plastic protectants create barrier films that block harmful ultraviolet radiation while maintaining natural appearance. Avoid petroleum-based products that can soften plastic materials and cause premature failure.

Seasonal Care Procedures

Winter preparation includes thorough cleaning and inspection before freezing weather arrives. Remove all debris from drainage channels that could freeze and crack cap materials. Apply protectant products to create moisture barriers that prevent freeze-thaw damage in vulnerable areas.

Spring maintenance reverses winter damage and prepares caps for active season use. Inspect for freeze damage, salt corrosion, and UV degradation accumulated during harsh winter months. Address minor damage immediately before summer heat accelerates deterioration processes.

Summer care focuses on UV protection and thermal stress management. Park in shaded areas when possible to reduce heat loading on plastic components. Check cap attachment more frequently during hot weather when thermal expansion stresses adhesive bonds and mounting points.

Fall preparation includes comprehensive cleaning and protective treatment before winter weather arrives. Remove accumulated dirt and contaminants that accelerate freeze damage. Apply fresh protectant coatings to provide maximum protection through harsh winter conditions.

Troubleshooting Common Problems

Loose corner caps create rattling noises and compromise weather sealing. Immediate replacement prevents complete detachment and potential loss on highways. Don’t attempt temporary fixes with additional adhesive—proper installation requires complete removal and surface preparation.

Water leaks around cap areas indicate failed sealing or damaged components. Check for cap damage, improper installation, or worn surrounding seals. Address all related components simultaneously to prevent repeated leak problems from overlooked issues.

Color fading signals UV damage beginning but doesn’t require immediate replacement. Continue monitoring fade progression and plan replacement when aesthetic appearance becomes unacceptable. Color fade indicates material degradation that will lead to brittleness and cracking over time.

Drainage problems cause water pooling and potential freeze damage. Clear blocked channels with compressed air or small brushes. Persistent drainage problems may indicate cap damage or improper installation requiring professional evaluation.

Sourcing Quality Replacement Caps

Finding genuine BAKFlip corner cap replacement components requires identifying authorized dealers and verified suppliers. The aftermarket floods retailers with counterfeit parts that compromise performance and void warranties. Careful sourcing ensures authentic components that restore original equipment performance.

Authorized BAK Industries dealers represent the most reliable source for genuine replacement parts. These dealers maintain direct relationships with BAK Industries, ensuring authentic inventory and proper part identification. Use BAK’s dealer locator tool to find authorized retailers in your area.

Online retailers like Amazon, RealTruck, and AutoAnything sell genuine parts but require careful seller verification. Check seller credentials and customer reviews to identify authorized dealers versus third-party sellers of questionable authenticity. Purchase only from highly-rated sellers with established track records of genuine parts sales.

Direct purchasing from BAK Industries guarantees authenticity but may involve longer delivery times and higher shipping costs. Use this option for hard-to-find components or when local dealers can’t source specific parts. BAK’s customer service provides technical support and installation guidance.

Price Comparison Strategies

Compare total costs including shipping, taxes, and installation when evaluating suppliers. The lowest initial price rarely provides best value when additional costs are included. Free shipping thresholds encourage ordering multiple components simultaneously for better overall value.

Seasonal sales provide opportunities for significant savings on replacement parts. Black Friday, spring, and fall promotions often discount tonneau cover components 15-25%. Stock up on commonly replaced items during sale periods for future maintenance needs.

Bundle orders with related maintenance items for better shipping value and coordinated replacement schedules. Order corner caps with seals, latches, or cleaning supplies to justify shipping costs and have everything needed for comprehensive maintenance.

Consider warranty implications when price shopping. Saving $20 on questionable parts could void $500 worth of warranty coverage for related failures. Factor warranty protection into cost calculations for accurate value comparisons.

Professional Installation Services

While BAKFlip corner cap replacement suits most DIY skill levels, professional installation offers advantages for truck owners lacking time, tools, or confidence for quality results. Professional technicians complete installations quickly with guaranteed results and proper warranty coverage.

Authorized service centers employ technicians trained specifically on BAKFlip products and replacement procedures. These professionals handle installations daily, developing expertise that ensures perfect results and efficient completion times. Many service centers guarantee their work with extended warranties.

Mobile installation services bring professional expertise to your location, eliminating shop visits and minimizing downtime. Mobile technicians carry specialized tools and complete inventories for efficient on-site repairs. This convenience justifies higher labor costs for busy professionals.

Dealership service departments offer installation expertise plus warranty compliance for customers concerned about coverage preservation. Factory-authorized installations maintain full warranty protection and provide documented service records for future reference.

Cost-Benefit Analysis

Professional installation costs $75-150 depending on location and service provider complexity. Compare this cost against potential DIY mistakes requiring professional correction. Damaged panels from improper installation procedures can cost hundreds of dollars to repair.

Time savings justify professional installation for busy truck owners. Professional completion in 30-45 minutes versus DIY installations taking 2-3 hours provides clear time value for high-earning professionals. Consider your hourly earning rate when evaluating installation options.

Tool requirements for quality DIY installation include specialized adhesive removers, cleaning supplies, and proper application tools. Tool purchases for single-use applications often exceed professional installation costs while delivering inferior results from inexperience.

Warranty protection through professional installation provides peace of mind and documented service records. Professional installations rarely fail within warranty periods, while DIY mistakes can void coverage and create expensive repair obligations.

Frequently Asked Questions

How often should BAKFlip corner caps be replaced?

Typical BAKFlip corner cap lifespan ranges from 5-8 years depending on usage conditions and maintenance quality. Harsh climates, heavy use, and poor maintenance accelerate replacement needs. Inspect caps quarterly for cracking, fading, or loose attachment indicating replacement timing.

Can I use MX4 corner caps on other BAKFlip models?

Corner cap compatibility varies between BAKFlip models due to different panel dimensions and mounting systems. MX4 corner caps fit only MX4 covers—don’t attempt using them on G2, F1, or other models. Check part numbers and compatibility charts before ordering replacements.

What causes corner caps to fail prematurely?

Common causes include impact damage from cargo, UV degradation from sun exposure, chemical damage from harsh cleaners, and poor installation with contaminated surfaces. Proper maintenance and gentle handling extend cap service life significantly.

Are aftermarket corner caps worth the cost savings?

Aftermarket caps rarely provide good value despite lower initial costs. Shorter service life, poor fit, and warranty issues make genuine parts more economical long-term. Factor replacement frequency and potential warranty voids into cost calculations.

Can damaged corner caps affect tonneau cover operation?

Damaged caps can interfere with proper panel folding and weather sealing. Cracked caps may catch during folding operations while missing caps compromise weatherproof protection. Replace damaged caps promptly to maintain optimal cover performance.

What tools are needed for corner cap replacement?

Basic replacement requires plastic pry tools, adhesive remover, cleaning supplies, and new caps. Avoid metal tools that scratch panels. Heat guns or hair dryers help soften stubborn adhesive. Allow 24 hours curing time for proper adhesive bonding.

Do corner caps come with installation instructions?

Genuine BAKFlip replacement caps include detailed installation instructions with photos and troubleshooting tips. Instructions cover surface preparation, adhesive application, and curing requirements. Follow instructions carefully for optimal results and warranty compliance.

Can I repair cracked corner caps instead of replacing them?

Small cosmetic cracks accept temporary plastic repair compounds, but structural damage requires complete replacement. Repaired caps rarely maintain proper weather sealing or impact protection. Replacement provides better long-term value than attempted repairs.