BAKFlip G2 Parts & Replacement Components

BAKFlip G2 Corner Cap Replacement Kit

Part BAK-225408 includes 4 high-impact ABS corner caps with mounting hardware specifically engineered for G2 aluminum panels. These caps protect panel edges from cargo damage while maintaining precise weatherproof sealing. Temperature-tested from -40°F to 180°F for year-round durability. Installation takes 10 minutes with no drilling required—simply remove old caps and snap new ones into place. Each kit includes adhesive strips for secure mounting. Compatible with all BAKFlip G2 truck bed lengths including 5.5ft, 6.5ft, and 8ft configurations across Ford F-150, Chevy Silverado, RAM 1500, and Toyota Tundra applications.

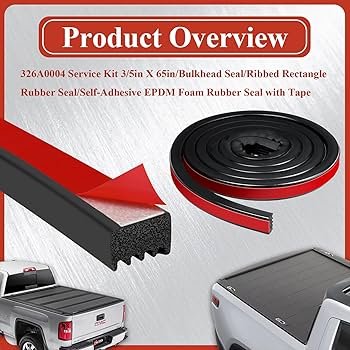

BAKFlip G2 Rubber Seal Replacement Kit

Part BAK-225410 provides complete perimeter seal set with pre-cut lengths for exact bed dimensions. Premium EPDM rubber compound resists UV degradation and maintains flexibility through extreme temperature cycling. Self-adhesive backing simplifies installation—clean existing rails, peel protective backing, and press into grooved channels. Creates complete weatherproof barrier preventing rain, snow, and dust intrusion into truck bed cargo area. Replace every 5-7 years or when water leaks appear. Kit includes extra seal material for future repairs and maintenance. Essential component for maintaining weatherproof protection that makes BAKFlip covers industry leaders.

BAKFlip G2 Latch Mechanism Assembly

Part BAK-225415 complete buckle and latch assembly restores automatic panel engagement when springs weaken or buckles wear. Stainless steel construction with polymer housing resists corrosion in harsh weather conditions. Spring-loaded mechanism engages automatically as panels close—no manual locking steps required. Installation requires basic hand tools and takes approximately 20 minutes per latch. Kit includes mounting hardware and adjustment instructions for proper panel alignment. Replace when latches feel loose, require excessive force to close, or panels pop open during highway driving. Compatible with all BAKFlip G2 models regardless of truck manufacturer or bed length.

BAKFlip G2 Side Rail Assembly

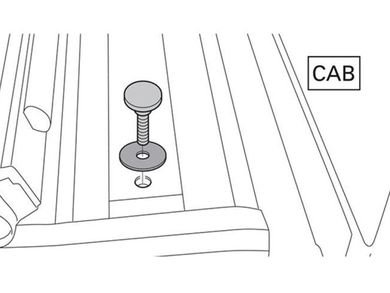

Complete extruded aluminum rail with integrated clamp system and mounting hardware for single-side replacement after damage or wear. Provides structural foundation for panel operation while maintaining lightweight construction. Part numbers vary by truck bed length—measure from inside bulkhead to inside tailgate for correct sizing. Rails feature integrated drainage channels directing water away from cargo and preventing pooling. No-drill clamp system installs in 30-45 minutes using basic hand tools. Rubber cushions between clamps and bed rails prevent paint damage during installation. Genuine BAK Industries construction ensures proper fit and maintains warranty coverage. Available for all G2-compatible truck models.

BAKFlip G2 Complete Hardware Kit

Part BAK-225420 includes all clamps, bolts, washers, and mounting brackets required for complete cover installation or hardware replacement. Stainless steel and zinc-coated fasteners resist corrosion through years of weather exposure. Essential replacement when hardware gets lost during cover removal for truck modifications or repairs. Universal compatibility across all G2 models eliminates fitment guesswork. Kit includes torque specifications and installation sequence guide for proper assembly. Extra clips and fasteners provide spares for future maintenance needs. Professional-grade components match original equipment specifications. Perfect for DIY enthusiasts and professional installers maintaining tonneau cover systems long-term.

Understanding BAKFlip G2 Parts and Components

The BAKFlip G2 parts system represents years of engineering refinement focused on creating components that withstand extreme conditions while maintaining precise operation. Unlike generic tonneau covers using universal hardware, every G2 component serves specific functions in the overall system. Understanding how these parts work together helps truck owners maintain peak performance and recognize when replacement becomes necessary.

Each G2 component undergoes rigorous testing including temperature cycling, UV exposure, and mechanical stress simulation. Corner caps endure impact testing equivalent to years of cargo loading. Seals face accelerated aging tests simulating decade-long exposure. Latch mechanisms cycle thousands of times under load to verify spring durability and engagement reliability.

This comprehensive testing ensures bakflip g2 replacement parts restore original performance rather than providing temporary fixes. When you invest in genuine components, you’re purchasing the same engineering standards that made your cover reliable initially. Generic alternatives lack this testing and often fail within months of installation.

Why Genuine Parts Matter for G2 Performance

The BAKFlip G2’s aluminum construction demands precise tolerances that aftermarket parts can’t match. Corner caps must fit exactly to maintain panel alignment and weather sealing. Generic caps often run slightly oversized or undersized, creating gaps that allow water intrusion or binding that prevents smooth folding operation.

Genuine bakflip g2 parts maintain the engineering relationships between components. Seal compression rates match rail dimensions exactly. Latch spring tension coordinates with panel weight for effortless operation. Hardware torque specifications prevent over-tightening that cracks rails or under-tightening that allows movement and leaks.

Using non-genuine parts disrupts these carefully engineered relationships. A seal that’s slightly too thick prevents complete panel closure. Corner caps with wrong mounting angles create stress points that crack panels. These seemingly minor differences compound into major operational problems that compromise your truck bed’s weather protection and security.

G2 Construction and Component Integration

The BAKFlip G2’s four-panel aluminum construction creates unique engineering challenges that other folding covers avoid. Each panel must maintain rigidity independently while connecting smoothly to adjacent panels. The hinge system allows complete 180-degree folding while sealing weathertight when closed.

This sophisticated design requires specialized replacement components engineered specifically for aluminum panel construction. Steel-cover parts won’t work—different thermal expansion rates create binding in cold weather and gaps in heat. Vinyl cover components lack the structural strength aluminum panels demand from mounting hardware.

Understanding this integration helps explain why genuine BAKFlip G2 replacement parts cost more than universal alternatives. You’re paying for engineering specificity that ensures your cover continues operating as designed. Generic parts represent compromises that sacrifice performance for lower cost.

BAKFlip G2 Parts Diagram and Identification

The official bakflip g2 parts diagram provides exploded views showing every component relationship and proper assembly sequence. This technical illustration proves invaluable for identifying specific parts, understanding assembly procedures, and troubleshooting operational problems. BAK Industries provides downloadable PDF versions through their technical support section.

Each diagram component carries a callout number corresponding to specific part numbers in BAK’s catalog system. When contacting customer service or dealers, reference these callout numbers for precise identification. This eliminates confusion between similar-looking components and ensures you receive exactly the right replacement parts.

The diagram separates major assemblies—rail system, panel construction, latching mechanisms, and sealing components. Each section shows how individual parts connect and interact. This visual reference helps DIY installers understand assembly sequences and identify which components need replacement during troubleshooting.

Reading the Parts Diagram Effectively

Start with the main assembly view showing the complete cover installed on a generic truck bed. This overview identifies major component groups and their relationships. Detailed breakout sections zoom into specific assemblies like latch mechanisms or corner cap installations.

Each numbered callout connects to a parts list showing part numbers, quantities required, and basic specifications. Some components appear multiple times—corner caps use the same part number but require four pieces total. Understanding these quantity requirements prevents ordering insufficient replacement parts.

Pay attention to assembly notes and warnings included in diagram margins. These highlight critical installation sequences, torque specifications, and compatibility information. Ignoring these details can result in improper installation or component damage during assembly.

Digital and Printed Reference Options

Download digital copies of the bakflip g2 parts diagram to your phone for reference during repairs or parts ordering. Digital versions allow zooming into specific sections for detailed examination of complex assemblies. Save multiple copies in different locations to prevent losing access during critical repair situations.

Print key diagram sections for workshop reference during hands-on repairs. Paper copies resist damage from grease and dirt that can damage electronic devices. Laminated prints provide durability for frequent reference during multiple repair projects.

Keep copies in your truck’s glove box for emergency reference during road trips or when problems develop away from home. Having immediate access to part numbers and basic assembly information helps you communicate effectively with distant dealers or service centers.

Common G2 Parts Replacement Timeline

Understanding typical replacement schedules for bakflip g2 parts helps truck owners budget for maintenance and catch problems before they cause expensive damage. Different components wear at different rates depending on usage patterns, climate conditions, and maintenance quality.

High-Wear Components (3-5 Years)

Corner caps typically need replacement every 3-5 years depending on cargo handling frequency and impact severity. Frequent loading of sharp or heavy items accelerates wear. Caps in hot climates may crack sooner from UV exposure and thermal cycling. Regular inspection helps catch hairline cracks before complete failure.

Latch mechanisms wear from thousands of open-close cycles. Spring tension weakens gradually—first requiring slightly more force to close, eventually failing to engage automatically. Most owners notice latch degradation after 4-6 years of regular use. Commercial applications may need replacement sooner.

Rubber seals degrade from environmental exposure more than mechanical wear. UV radiation, ozone, and temperature cycling gradually harden rubber compounds. Seals in sunny climates typically need replacement every 4-5 years. Northern climates may extend seal life to 6-7 years due to reduced UV exposure.

Medium-Wear Components (7-10 Years)

Rail hardware and clamps generally last 7-10 years unless damaged by accidents or over-tightening during installation. Stainless steel components resist corrosion effectively. Problems usually result from installation errors rather than normal wear. Regular inspection prevents small issues from becoming major failures.

Hinge assemblies benefit from the G2’s robust aluminum construction. Properly maintained hinges often last the cover’s entire service life. Problems typically develop from lack of lubrication allowing dirt accumulation rather than mechanical wear. Annual cleaning and lubrication prevents premature hinge replacement.

Long-Term Components (10+ Years)

Aluminum panels rarely need replacement unless damaged by accidents, severe weather, or improper handling. The G2’s thick aluminum construction resists denting and cracking from normal use. When panels do need replacement, it’s usually more cost-effective to purchase a complete new cover.

Rails and structural components typically last the cover’s entire service life when properly installed and maintained. Failures usually result from accidents, over-tightening during installation, or modification attempts. These structural components justify the G2’s premium pricing through exceptional longevity.

Professional Installation vs DIY Replacement

Most bakflip g2 replacement parts install easily with basic mechanical skills and common hand tools. Corner caps, seals, and hardware replacements represent straightforward maintenance that most truck owners handle successfully. However, some repairs benefit from professional expertise and specialized tools.

DIY-Friendly Replacements

Corner cap replacement requires no special tools or skills. Old caps pop off easily—sometimes too easily when they’re ready for replacement. New caps snap into place with firm pressure. The entire job takes 15-20 minutes and requires only basic cleaning supplies for surface preparation.

Seal replacement demands patience and attention to detail but uses simple techniques. Clean old adhesive completely, align new seals carefully, and press firmly for complete adhesion. Take time getting alignment right—rushing leads to gaps that compromise weather sealing. Allow adhesive to cure before operating the cover.

Basic hardware replacement uses standard socket wrenches and screwdrivers. Follow torque specifications carefully to prevent over-tightening that cracks aluminum rails. Under-tightening allows movement that creates leaks and accelerates wear. A torque wrench eliminates guesswork and ensures proper installation.

Professional Installation Benefits

Latch mechanism replacement involves precise adjustment procedures that professionals handle routinely. Improper spring orientation or adjustment causes binding, excessive force requirements, or failure to engage. Professionals complete these adjustments quickly and test operation thoroughly before finalizing installation.

Rail replacement or major repairs require cover removal and precise realignment during installation. Professionals have experience maintaining panel alignment and preventing damage during disassembly. They also stock replacement hardware for components that break during removal.

Professional installers guarantee their work and fix problems at no additional charge. DIY mistakes can cost more than professional installation when you factor in damaged components, repeated parts orders, and time spent troubleshooting problems.

Choosing the Right Approach

Consider your mechanical experience, available tools, and time constraints when deciding between DIY and professional installation. Simple replacements make sense for mechanically inclined owners. Complex repairs or if you lack proper tools may justify professional service.

Factor in the cost of mistakes when making decisions. A $40 seal kit becomes a $200 problem if improper installation damages rails requiring professional correction. Sometimes paying for professional installation initially costs less than fixing DIY mistakes later.

Many authorized BAKFlip dealers offer installation services at reasonable rates. Some provide free installation when you purchase parts through them. This adds value and ensures warranty compliance for your replacement components.

Sourcing Genuine BAKFlip G2 Parts

Finding authentic bakflip g2 parts ensures proper fit, warranty compliance, and long-term performance. Multiple legitimate sources exist, each offering different advantages based on your specific needs, timeline, and support requirements.

Authorized Dealer Network

BAK Industries maintains an extensive network of authorized dealers specializing in truck accessories and tonneau cover systems. These dealers receive technical training, stock genuine replacement parts, and provide installation support. Use BAK’s dealer locator tool to find nearby authorized retailers.

Authorized dealers offer expert consultation for complex repairs or when you’re unsure which components need replacement. They can examine photos, discuss symptoms, and recommend complete repair solutions rather than piecemeal replacements. Many provide package pricing for multiple components replaced simultaneously.

Dealer installation services often include warranty coverage on labor and guarantee proper installation. If problems develop after professional installation, dealers correct issues at no additional charge. This protection proves valuable for complex repairs or when working with expensive components.

Online Retailers and Marketplaces

Amazon, RealTruck, and AutoAnything sell genuine BAKFlip parts with competitive pricing and fast shipping. Verify seller information confirms authorized dealer status before ordering. Customer reviews provide real-world experiences with specific parts and installation procedures.

Online ordering works well when you know exact part numbers and don’t need immediate technical support. Compare pricing across multiple retailers but verify shipping costs and return policies. Some components like custom-length seals aren’t returnable once opened.

Watch for counterfeit parts on marketplace platforms where anyone can sell. Genuine BAK Industries parts include specific packaging, part number formatting, and quality characteristics. When in doubt, purchase from established retailers with return policies rather than unknown sellers offering suspiciously low prices.

Direct from BAK Industries

BAK Industries customer service sells bakflip g2 parts directly for guaranteed authenticity. This works best for hard-to-find components or when you need technical guidance choosing correct replacements. BAK’s technical support staff provides detailed fitment information and installation guidance.

Direct ordering typically takes longer than dealers or online retailers due to centralized inventory shipping. Budget extra time for delivery, especially during peak seasons or for special-order items. However, you receive absolute assurance of genuine components with full warranty coverage.

BAK Industries often provides technical bulletins and updates when ordering directly. These documents include updated installation procedures, compatibility information, and maintenance recommendations that improve component longevity and performance.

Maintenance Tips for Extended Parts Life

Proper maintenance significantly extends bakflip g2 parts service life and reduces replacement frequency. Simple care routines prevent premature wear and catch developing problems before they require expensive repairs or replacement.

Regular Cleaning and Inspection

Wash your G2 cover monthly with mild automotive soap and water to remove dirt, salt, and debris that accelerate component wear. Pay special attention to panel gaps, hinge areas, and rail channels where debris accumulates. Use soft brushes to clean drainage channels without damaging seals or finishes.

Inspect corner caps during each cleaning for hairline cracks, looseness, or damage from cargo contact. Early detection allows replacement before caps fail completely and potentially damage panels. Look for stress whitening in black plastic caps—an early indicator of material fatigue.

Check seal condition quarterly by running your finger along seal surfaces feeling for hardening, cracking, or permanent compression. Healthy seals feel flexible and spring back after compression. Worn seals remain flat or show visible cracking requiring immediate replacement.

Lubrication and Protection

Apply silicone spray to rubber seals every three months to maintain flexibility and prevent premature aging. Avoid petroleum-based products that damage rubber compounds. Light silicone coating also helps seals resist UV damage and temperature extremes.

Lubricate latch mechanisms twice yearly with dry lubricant to prevent binding and reduce spring wear. Focus on pivot points, spring housings, and engagement surfaces. Wipe away excess lubricant that attracts dirt and debris.

Treat aluminum panels with appropriate aluminum protectant products to maintain finish and prevent oxidation. This cosmetic maintenance also makes cleaning easier and helps identify damage early when panels stay clean and bright.

Seasonal Maintenance Schedule

Spring preparation includes thorough cleaning after winter salt exposure, complete lubrication of all moving parts, and inspection for winter damage. Replace any components showing wear before heavy use season begins.

Fall maintenance prepares the cover for winter weather with seal inspection, drainage channel clearing, and protective treatments. Address any developing problems before cold weather makes repairs difficult.

Document maintenance activities and component conditions to track wear patterns and plan replacement timing. Photos help identify gradual changes that might not be obvious during routine inspections.

Frequently Asked Questions

How do I identify which BAKFlip G2 generation I own?

Check your purchase date and serial number to determine generation. G2 models manufactured after 2019 include updated corner cap designs and improved sealing systems. Contact BAK Industries customer service with your serial number for definitive generation identification and compatible parts information.

Are BAKFlip G2 parts compatible with other BAKFlip models?

Some universal components like certain seals and hardware fit multiple BAKFlip models, but structural parts remain model-specific. Don’t assume parts interchange between G2, MX4, and F1 models without verifying compatibility through official parts diagrams or BAK Industries consultation.

Can I repair damaged G2 panels instead of replacing them?

Minor scratches and small dents sometimes accept repair with specialized aluminum repair techniques. However, cracked panels or significant structural damage requires complete replacement to maintain weather sealing and operational integrity. Consult professionals for damage assessment.

What causes premature latch mechanism failure?

Most latch problems result from lack of lubrication allowing dirt accumulation or over-tightening during installation creating excessive spring tension. Regular cleaning and proper lubrication prevent most premature failures. Replace latches when springs weaken rather than adjusting for temporary fixes.

How long do genuine G2 replacement parts typically last?

Corner caps and seals typically last 5-7 years with proper maintenance. Latch mechanisms often exceed 8-10 years when regularly lubricated. Structural components like rails usually last the cover’s entire service life. Climate conditions and usage patterns affect all component lifespans.

Will using aftermarket parts void my G2 warranty?

Yes, installing non-genuine BAK Industries parts voids warranty coverage. If critical components fail and BAK discovers aftermarket parts during inspection, they can deny warranty claims. The money saved on cheaper parts risks losing coverage for expensive structural repairs.

Where can I download the official G2 parts diagram?

Visit BAK Industries’ website support section for downloadable PDF parts diagrams. These technical documents include part numbers, assembly sequences, and compatibility information. Register your cover for access to model-specific documentation and technical updates.

What tools are required for most G2 parts replacement?

Basic replacements require socket wrench sets, screwdrivers, and cleaning supplies. A torque wrench helps ensure proper hardware installation. More complex repairs might need specialized tools, but routine maintenance uses equipment most truck owners already possess.