BAKFlip MX4 vs FiberMax | Complete Comparison Guide

BAKFlip MX4 Aluminum Folding Cover

All-aluminum construction provides exceptional durability while maintaining lightweight operation. Four-panel folding design allows complete bed access without removal. Premium weather sealing with EPDM rubber gaskets creates waterproof barrier. Automatic latching buckles secure panels without manual locking. No-drill installation uses heavy-duty clamps that won’t damage truck bed rails. Compatible with most bed accessories including toolboxes and bed liners. Five-year manufacturer warranty covers defects and premature failures.

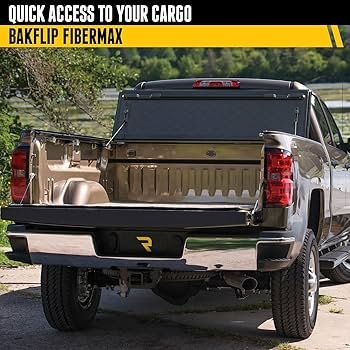

BAKFlip FiberMax Fiberglass Construction

Fiberglass composite panels offer superior impact resistance and paint-like finish durability. Four-panel design matches MX4 functionality with complete folding capability. Integrated drainage system prevents water accumulation in panel joints. Advanced weather stripping provides enhanced sealing compared to entry-level covers. Reinforced corner construction withstands cargo impacts that crack cheaper alternatives. Professional appearance complements truck styling with smooth, painted finish that resists UV fading.

Material Construction: Aluminum vs Fiberglass

The fundamental difference between BAKFlip MX4 vs FiberMax lies in their core construction materials, each offering distinct advantages for different user priorities. The MX4’s all-aluminum construction provides exceptional strength-to-weight ratio, making daily operation effortless while delivering commercial-grade durability. Every panel uses marine-grade aluminum that won’t rust, corrode, or degrade from weather exposure over decades of service.

Aluminum’s inherent properties make the BAKFlip MX4 naturally resistant to temperature extremes, chemical exposure, and UV radiation without protective coatings that eventually fail. The material maintains structural integrity through temperature swings from -40°F to 180°F, making it ideal for harsh climates where fiberglass might become brittle or crack. Additionally, aluminum’s lighter weight reduces stress on hinges and latching mechanisms, extending component lifespan.

The FiberMax uses advanced fiberglass composite construction that excels in impact resistance and aesthetic appeal. Fiberglass panels absorb impacts that might dent aluminum, making them superior for users who frequently haul heavy cargo or tools. The composite construction allows for smooth, painted finishes that perfectly match factory truck colors and maintain their appearance longer than bare aluminum.

However, fiberglass construction adds weight that affects daily operation and long-term component wear. The FiberMax weighs approximately 15-20 pounds more than comparable MX4 models, requiring more effort to fold panels and putting additional stress on hinges during thousands of open-close cycles. This weight penalty becomes noticeable during frequent use and may accelerate wear on moving components.

Durability and Longevity Factors

When comparing BAKFlip MX4 vs FiberMax durability, both covers deliver excellent longevity but excel in different failure modes. The MX4’s aluminum construction resists catastrophic failures—it may dent from extreme impacts but rarely cracks or breaks completely. Surface scratches can be polished out or simply ignored without affecting structural performance.

Fiberglass composite construction in the FiberMax provides superior impact absorption but can suffer chip damage from sharp impacts or extreme cold. While the material resists denting better than aluminum, chips and cracks require immediate attention to prevent water intrusion and structural degradation. However, fiberglass repairs are often more straightforward than aluminum damage correction.

Long-term UV exposure affects both materials differently. Aluminum naturally resists UV degradation without protective coatings, maintaining strength indefinitely. The MX4’s powder-coated finish may fade but doesn’t affect structural integrity. FiberMax panels rely on protective gel coats that eventually degrade from UV exposure, requiring restoration or refinishing to maintain appearance and weather protection.

Weather Protection and Sealing Performance

Both covers deliver exceptional weather protection, but their sealing approaches differ significantly. The BAKFlip MX4 uses precision-machined aluminum edges with EPDM rubber seals that compress evenly for consistent weather protection. The rigid aluminum structure maintains seal compression even as temperature changes cause expansion and contraction.

The FiberMax employs advanced weather stripping with multiple seal points that conform better to irregularities in truck bed rails. Fiberglass panels’ flexibility allows better adaptation to slight misalignments or wear in mounting points. This adaptability can provide superior long-term sealing as truck beds settle or develop minor warping over years of use.

Water intrusion testing shows both covers perform excellently in normal conditions, but the MX4 excels in extreme weather due to its rigid construction maintaining consistent seal pressure. High winds that might cause flexible panels to flutter and break seals have minimal effect on the aluminum MX4’s structural integrity.

Drainage System Design

The BAKFlip MX4 incorporates integrated drainage channels in its side rail system that direct water away from cargo areas efficiently. These channels are machined into aluminum rails, ensuring long-term effectiveness without clogging or degradation. The system handles heavy rainfall and snow melt without allowing water accumulation in panel joints.

FiberMax covers feature molded drainage systems that integrate seamlessly with panel construction. The fiberglass material allows for more complex drainage geometries that can handle larger water volumes in extreme weather. However, these systems may be more susceptible to clogging from debris and require more frequent cleaning to maintain optimal performance.

Both systems prevent the water pooling issues common with cheaper tonneau covers, but the MX4’s aluminum channels maintain their effectiveness longer due to the material’s resistance to corrosion and wear. Regular maintenance keeps both systems functioning properly, but aluminum requires less frequent attention.

Installation Process and Complexity

Installation procedures for BAKFlip MX4 vs FiberMax are nearly identical, both using no-drill clamp systems that secure to truck bed rails without permanent modifications. However, weight differences create practical considerations during installation and adjustment processes.

The MX4’s lighter weight makes it manageable for single-person installation on most truck models. The aluminum panels lift easily for alignment adjustments, and the entire cover can be repositioned if initial placement isn’t optimal. This ease of handling reduces installation time and frustration, especially for DIY installers working alone.

FiberMax installation requires more caution due to increased weight and fiberglass panels’ potential for chip damage if dropped or mishandled. Two-person installation is recommended for larger truck beds to prevent damage and ensure proper alignment. The extra weight also requires careful attention to clamp torque specifications—under-tightening allows movement while over-tightening can crack fiberglass panels.

Adjustment and Fine-Tuning

Both covers require initial adjustment after installation, but the MX4’s rigid aluminum construction holds adjustments longer once properly set. The material’s dimensional stability means settings established during installation remain consistent through temperature changes and normal use.

The FiberMax may require periodic readjustment as fiberglass panels experience slight dimensional changes from temperature cycling and stress relief. This isn’t necessarily a disadvantage—the material’s flexibility allows better adaptation to truck bed irregularities that might cause rigid panels to bind or seal poorly.

Professional installers often prefer working with aluminum covers like the MX4 because adjustments hold reliably and warranty callbacks are less frequent. However, experienced installers appreciate fiberglass covers’ ability to compensate for truck bed imperfections that rigid materials can’t accommodate as easily.

Security Features and Cargo Protection

Security capabilities represent a crucial factor when comparing BAKFlip MX4 vs FiberMax for users who frequently leave valuable cargo in their truck beds. Both covers provide similar locking mechanisms and visual deterrence, but material properties create different security profiles.

The BAKFlip MX4’s aluminum construction offers excellent resistance to cutting and prying attempts. Aluminum’s toughness makes it extremely difficult to cut through with portable tools, and the material’s flexibility prevents shattering under impact. However, determined thieves with proper tools can eventually defeat aluminum barriers.

FiberMax panels resist different attack methods due to fiberglass composite construction. The material is virtually impossible to cut quickly with hand tools but can be more vulnerable to impact damage that creates access points. Fiberglass also tends to fail more catastrophically than aluminum when security barriers are breached.

Locking Mechanism Performance

Both covers use identical automatic latching systems that engage when panels close, eliminating the need for manual locking procedures. The system includes provisions for padlock security at the tailgate end, providing additional protection for high-value cargo.

The MX4’s lighter panels operate latching mechanisms with less stress, potentially extending component lifespan and maintaining consistent engagement over years of use. Lighter weight also reduces the likelihood of latches disengaging due to road vibration or impact.

FiberMax covers’ additional weight ensures positive latch engagement but may accelerate wear on spring-loaded components. However, the extra mass also provides better resistance to wind lifting that might stress latch mechanisms during highway driving.

Price Comparison and Value Analysis

Cost considerations significantly impact the BAKFlip MX4 vs FiberMax decision for budget-conscious truck owners. Typically, the MX4 commands a premium price due to aluminum construction costs and manufacturing complexity, while FiberMax models offer similar functionality at lower initial investment.

The BAKFlip MX4 generally costs $200-400 more than comparable FiberMax models, depending on truck application and dealer pricing. This premium reflects aluminum material costs, precision manufacturing requirements, and the cover’s positioning as BAK’s flagship aluminum folding model.

However, long-term value calculations often favor the MX4 due to reduced maintenance requirements and longer component lifespan. Aluminum’s corrosion resistance eliminates refinishing needs, while the lighter weight reduces wear on moving parts. Over a decade of ownership, these advantages can offset the higher initial purchase price.

Total Ownership Cost Factors

FiberMax covers offer lower entry costs but may require periodic maintenance like gel coat restoration or weather seal replacement more frequently than aluminum alternatives. Fiberglass repairs, while feasible, often require professional services that add to long-term ownership costs.

The MX4’s aluminum construction maintains performance with minimal maintenance beyond routine cleaning and lubrication. Replacement parts are readily available and often less expensive than fiberglass components. The material’s repairability also makes collision damage less costly to address.

Resale value considerations favor aluminum covers in most markets. The MX4 typically retains higher percentages of original value when selling used trucks or transferring covers to new vehicles. This factor partially offsets the higher initial investment for owners who change trucks frequently.

Truck Model Compatibility and Fitment

Both BAKFlip MX4 and FiberMax models offer extensive truck compatibility across popular pickup models including Ford F-150, Chevrolet Silverado, GMC Sierra, RAM 1500, Toyota Tundra, and Nissan Titan. However, specific fitment details may vary between construction types.

The MX4’s standardized aluminum construction allows consistent fitment across different truck models with minor adjustments to accommodate bed rail variations. This standardization simplifies inventory for dealers and ensures reliable fitment regardless of specific truck configuration.

FiberMax models may offer more truck-specific optimization due to fiberglass molding flexibility during manufacturing. This can result in better initial fit for specific applications but may limit transferability between different truck models.

Bed Length and Configuration Options

Both cover lines accommodate standard bed lengths including 5.5-foot, 6.5-foot, and 8-foot configurations across their supported truck models. Special applications like crew cab short beds and extended cab long beds receive coverage in both product lines.

The BAKFlip MX4’s modular design allows easier adaptation to unusual bed configurations or custom applications. Aluminum’s workability enables modifications that might be difficult or impossible with molded fiberglass panels.

Compatibility with truck bed accessories like bed liners, toolboxes, and tie-down systems is excellent for both covers. However, the MX4’s lower profile may provide better clearance for some gooseneck and fifth-wheel applications.

Performance in Extreme Conditions

Real-world performance testing reveals how BAKFlip MX4 vs FiberMax handles extreme weather, temperature variations, and challenging use conditions that many truck owners encounter annually.

In extreme cold conditions, the MX4’s aluminum construction maintains flexibility and strength down to -40°F without becoming brittle. The material’s thermal conductivity helps prevent ice buildup that can bind folding mechanisms. Seals remain pliable and effective even in Arctic conditions.

FiberMax performance in cold weather depends on specific composite formulation, but most fiberglass materials become more brittle as temperatures drop. Impact resistance decreases significantly in sub-zero conditions, making panels more susceptible to crack damage from cargo shifting or ice impact.

Hot Weather Performance

High temperature exposure affects both materials differently but generally favors aluminum construction. The MX4’s aluminum panels conduct heat efficiently, preventing excessive surface temperatures that could damage cargo or make panels uncomfortable to handle.

Fiberglass panels in the FiberMax can reach higher surface temperatures in direct sunlight due to lower thermal conductivity. However, this same property provides better insulation for temperature-sensitive cargo, potentially keeping truck bed contents cooler during extreme heat.

UV exposure degradation strongly favors aluminum construction over fiberglass. While both materials handle normal UV exposure well, decades of sun exposure eventually break down gel coats and protective finishes on fiberglass panels. Aluminum maintains structural properties indefinitely regardless of UV exposure levels.

Maintenance Requirements and Service Life

Long-term ownership satisfaction often depends more on maintenance requirements than initial purchase decisions. Understanding the care needs for BAKFlip MX4 vs FiberMax helps owners budget time and money for ongoing upkeep.

The BAKFlip MX4 requires minimal maintenance beyond routine washing and periodic lubrication of moving components. Aluminum doesn’t require protective treatments, refinishing, or special cleaning products. A simple wash with car soap every few months maintains both appearance and function indefinitely.

FiberMax maintenance involves more attention to surface protection and periodic restoration of gel coat finishes. UV exposure gradually degrades protective coatings that require renewal every 3-5 years to maintain appearance and weather resistance. Specialized fiberglass cleaners and polishes add to ongoing ownership costs.

Component Replacement Schedules

Wear component replacement follows predictable schedules for both covers. Seals typically need replacement every 5-7 years regardless of cover construction. Latch mechanisms may require service or replacement every 7-10 years depending on usage frequency.

The MX4’s lighter weight reduces stress on hinges and mounting hardware, potentially extending replacement intervals for these components. Aluminum’s corrosion resistance ensures structural components never need replacement due to material degradation.

FiberMax covers may experience more frequent hardware wear due to increased panel weight and stress on moving components. However, the composite construction rarely suffers structural failures that require panel replacement unless damaged by impact or extreme weather.

Professional vs DIY Installation Considerations

Installation complexity affects total ownership costs and initial satisfaction with either BAKFlip MX4 or FiberMax covers. Understanding which installation challenges each design presents helps owners decide between professional installation and DIY approaches.

DIY installation strongly favors the MX4 due to its lighter weight and aluminum’s forgiving nature during adjustment procedures. Most mechanically-inclined truck owners can successfully install an MX4 with basic tools and careful attention to instructions. Mistakes during alignment or adjustment rarely cause permanent damage.

The FiberMax requires more careful handling during installation due to fiberglass panels’ potential for chip or crack damage. Professional installation becomes more attractive when factoring in the risk of damaging expensive panels during amateur installation attempts.

Warranty Implications

Both covers include comprehensive manufacturer warranties, but installation-related damage can void coverage if not performed correctly. Professional installation often includes guarantees that protect against fitting errors or damage during the installation process.

The MX4’s installation tolerance makes warranty-voiding mistakes less likely during DIY installation. Aluminum’s durability means minor installation errors rarely cause permanent damage that affects warranty coverage.

FiberMax installation mistakes can more easily cause damage that voids warranty protection. Cracked panels from over-tightened clamps or chipped edges from mishandling create expensive repair needs not covered under manufacturer warranties.

Final Recommendation: Which Cover Suits Your Needs

Choosing between BAKFlip MX4 vs FiberMax ultimately depends on prioritizing specific performance characteristics and use patterns that match your truck ownership style and cargo hauling needs.

Select the BAKFlip MX4 if you prioritize long-term durability, minimal maintenance, frequent operation, or plan to keep your truck for many years. The aluminum construction excels in harsh climates, commercial use, and situations where cover weight matters for daily operation. Despite higher initial costs, the MX4 often provides better long-term value through reduced maintenance and longer component life.

Choose the FiberMax if initial purchase price is a primary concern, you prefer painted finishes that match truck aesthetics, or your use patterns involve heavy cargo that might dent aluminum panels. The composite construction offers excellent impact resistance and can provide superior long-term appearance with proper maintenance.

Both covers deliver excellent weather protection, security, and functionality that surpasses cheaper alternatives significantly. Either choice provides years of reliable service that protects valuable cargo and enhances truck utility. The decision often comes down to personal preferences regarding maintenance involvement, budget priorities, and specific use requirements unique to your situation.

For most truck owners, the BAKFlip MX4 represents the better long-term investment despite higher upfront costs. Its aluminum construction, reduced maintenance needs, and operational advantages create ownership satisfaction that justifies the premium pricing. However, budget-conscious buyers will find excellent value in FiberMax models that deliver similar core functionality at lower initial cost.

Frequently Asked Questions

Which cover is better for extreme weather conditions?

The BAKFlip MX4 performs better in extreme conditions due to aluminum’s temperature stability and corrosion resistance. It maintains flexibility in extreme cold and doesn’t become brittle like fiberglass can. The aluminum construction also handles UV exposure better long-term without requiring protective coating maintenance.

How much weight difference exists between MX4 and FiberMax?

The FiberMax typically weighs 15-20 pounds more than comparable MX4 models due to fiberglass composite construction. This weight difference affects daily operation ease and long-term wear on hinges and latching mechanisms. The MX4’s lighter weight makes frequent operation less tiring and reduces component stress.

Can I install either cover myself without professional help?

The BAKFlip MX4 is more DIY-friendly due to its lighter weight and aluminum’s forgiveness during installation adjustments. FiberMax installation requires more careful handling to avoid damage to fiberglass panels. Both use no-drill clamp systems, but the MX4 presents lower risk of installation damage.

Which cover holds value better for resale?

Aluminum covers like the MX4 typically retain higher resale values due to their durability reputation and lower maintenance requirements. The premium construction and brand recognition help maintain value when selling trucks or transferring covers to new vehicles.

Do both covers work with truck bed accessories?

Yes, both BAKFlip MX4 and FiberMax are compatible with most truck bed accessories including bed liners, toolboxes, and tie-down systems. The MX4’s lower profile may provide slightly better clearance for some gooseneck and fifth-wheel applications, but both accommodate standard truck bed accessories well.

How do maintenance costs compare between the two covers?

The BAKFlip MX4 has lower long-term maintenance costs because aluminum doesn’t require protective coatings or refinishing. FiberMax covers need periodic gel coat restoration and may require more frequent seal replacement due to the heavier panels creating more stress on components. However, both covers are relatively low-maintenance compared to soft tonneau covers.