BAKFlip Hinge Replacement Guide | Rubber Seals & Parts

BAKFlip MX4 Hinge Seal Replacement Kit

Part BAK-356A0018 provides complete hinge seal replacement for all three panel connections on your MX4 tonneau cover. These UV-resistant EPDM rubber seals prevent water intrusion between folding panels while maintaining flexibility through thousands of fold cycles. Installation requires partial cover disassembly but restores weatherproof sealing when water leaks appear between panels. Each kit includes three pre-cut hinge seals with installation hardware and detailed instructions. Compatible with all BAKFlip MX4 models across F-150, Silverado, RAM 1500, and other full-size pickups.

BAKFlip G2 Rubber Hinge Replacement

Part BAK-262A0012 complete hinge seal set for G2 tonneau covers restores weatherproof sealing between aluminum panels. Premium rubber construction withstands temperature extremes from -40°F to 180°F without cracking or hardening. Signs your G2 needs hinge replacement include water intrusion between panels while perimeter seals remain intact. Installation takes 2-3 hours with basic hand tools and included hardware. Replace every 5-7 years or when visual inspection reveals cracking and brittleness. Genuine BAK Industries component ensures proper compression and exact fit specifications for reliable weather protection.

BAKFlip F1 Hinge Seal Kit

Part BAK-772A0008 designed specifically for F1 hard folding covers with integrated drain system compatibility. These precision-molded seals maintain proper water drainage while preventing intrusion during heavy rain and snow. The F1’s unique design requires specialized hinge seals that work with the cover’s drainage channels—generic seals block drainage and cause water backup. Installation involves hinge pin removal and careful seal positioning for proper compression. Each seal features molded drain grooves that align with F1 drainage pathways. Critical for maintaining the F1’s superior weather protection in extreme conditions.

BAKFlip Hinge Pin Assembly

Part BAK-356A0025 stainless steel hinge pin assembly replaces worn or damaged pivot points on all BAKFlip models. Pins wear from repeated folding cycles, dirt infiltration, and corrosion in harsh weather environments. Symptoms include binding during folding, loose panel connections, or visible pin wear upon inspection. Each assembly includes precision-ground stainless steel pins, nylon bushings, and retaining clips for smooth operation. Replace when pins show scoring, panels feel loose at connections, or folding requires excessive force. Installation requires hinge disassembly but restores smooth operation and tight panel connections for years of reliable service.

Understanding BAKFlip Hinge System Design

The BAKFlip hinge replacement process becomes straightforward once you understand how these innovative tonneau covers achieve their weatherproof folding action. Unlike traditional hinges with simple pivot points, BAKFlip covers use a sophisticated sealing system that maintains protection while allowing panels to fold completely against the cab. Every hinge point incorporates multiple sealing elements working together to prevent water intrusion.

Each hinge assembly consists of precision-machined aluminum brackets, stainless steel pivot pins, polymer bushings, and compression rubber seals. The aluminum brackets bolt directly to panel frames, providing structural strength while maintaining lightweight construction. Stainless steel pins resist corrosion and wear through thousands of fold cycles, while polymer bushings ensure smooth operation without metal-on-metal contact.

The critical component for weather protection is the rubber hinge seal—a specially molded EPDM compound that compresses between panels when closed. These seals create a continuous weatherproof barrier across the entire cover while remaining flexible enough to allow smooth folding. When hinge seals fail, water infiltrates between panels even though perimeter seals remain intact.

Common Hinge Failure Patterns

Most bakflip hinge seal replacement needs develop gradually over 5-7 years of normal use. UV exposure, ozone degradation, and temperature cycling eventually cause rubber compounds to harden and crack. The first signs appear as hairline cracks in seal edges that expand under compression stress. Early intervention prevents complete seal failure and potential water damage to cargo.

Mechanical hinge components fail differently than seals. Pivot pins wear from dirt contamination acting like grinding compound during folding cycles. Contaminated pins develop scoring and flat spots that cause binding and uneven wear on bushings. Visual inspection reveals shiny wear marks and dimensional changes in properly maintained pins.

Bushings fail when pins become worn or when excessive side loads stress the hinge assembly. Worn bushings allow panel misalignment and loose connections that accelerate other component failures. Replacing just pins while ignoring worn bushings leads to premature new pin failure and continued operational problems.

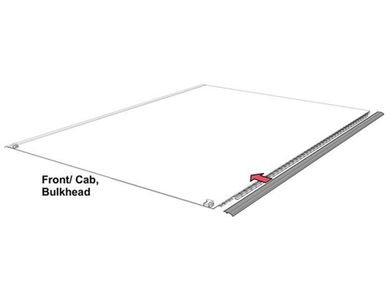

BAKFlip MX4 Hinge Replacement Procedures

Replacing bakflip mx4 hinge seal replacement components requires systematic disassembly to access internal hinge mechanisms. Start by fully opening the cover and securing all panels in the upright position against the cab. Remove cargo and clean the truck bed thoroughly to provide adequate workspace and prevent contaminating new seals during installation.

Begin disassembly by disconnecting the rear panel from side rails using appropriate socket wrenches. Support panel weight during removal to prevent damage to remaining hinge connections. Each panel weighs approximately 12-15 pounds, making single-person removal manageable with proper lifting technique and panel support.

Work systematically through each hinge connection, documenting the assembly sequence with photos before removing components. The MX4 uses specific orientation for seals and hardware that must be replicated during reassembly. Mark mating surfaces and hardware positions to ensure correct reconstruction of the complex hinge system.

Seal Installation Best Practices

Clean all sealing surfaces with isopropyl alcohol before installing new hinge seals. Residual dirt, old seal fragments, or cleaning product residue prevents proper seal compression and creates leak paths. Use lint-free cloths to avoid leaving fabric particles that interfere with seal contact surfaces.

New hinge seals require proper compression adjustment during installation. Too little compression allows water intrusion, while excessive compression causes premature seal wear and difficult folding operation. Follow BAK Industries torque specifications for mounting hardware to achieve optimal seal compression without damage.

Test seal compression by closing panels gently and checking resistance. Properly adjusted seals provide noticeable compression resistance without requiring excessive force. Uneven compression indicates misaligned components or incorrect installation sequence requiring correction before completing assembly.

Hinge Pin and Bushing Service

Inspect hinge pins for scoring, wear, or corrosion during seal replacement. Worn pins require replacement even if they appear functional—continuing service with damaged pins accelerates bushing wear and causes operational problems. Replacement pins must meet exact dimensional specifications for proper fit and smooth operation.

Remove old bushings carefully to avoid damaging hinge brackets during extraction. Polymer bushings may require gentle heating with a hair dryer to soften material for easier removal. New bushings install easily when properly sized but require precise alignment to prevent binding during pin installation.

Apply thin coat of marine-grade grease to pins before final assembly. This prevents corrosion and reduces friction during folding cycles. Avoid over-lubrication that attracts dirt and contaminants accelerating component wear. Clean excess grease from exposed surfaces before completing installation.

Model-Specific Hinge Replacement Differences

While all BAKFlip models share similar hinge design principles, specific components and procedures vary between the MX4, G2, and F1 series. Understanding these differences ensures ordering correct replacement parts and following appropriate installation procedures for your specific tonneau cover model.

BAKFlip MX4 Rubber Hinge Replacement

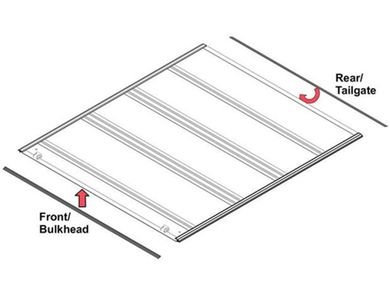

The bakflip mx4 rubber hinge replacement process involves three identical hinge assemblies connecting four aluminum panels. Each hinge uses the same seal design and hardware specifications, simplifying parts ordering and installation procedures. MX4 hinges incorporate integrated drainage channels that work with the cover’s water management system.

MX4 hinge seals feature molded drainage grooves that align with panel drainage systems. These grooves direct water away from seal compression points while maintaining weatherproof protection. Generic replacement seals lack these drainage features and compromise the MX4’s weather protection capabilities.

Installation requires partial cover disassembly but doesn’t involve complex drainage system reconnection like some competitive covers. The MX4’s integrated approach simplifies service while maintaining superior weather protection. Complete replacement typically takes 2-3 hours with basic hand tools and mechanical experience.

G2 Series Hinge Characteristics

G2 covers use reinforced hinge assemblies with larger pivot pins and bushings compared to the MX4. These components handle the G2’s heavier panel construction and provide extended service life in demanding applications. G2 hinge seals use different rubber compounds optimized for the model’s specific compression requirements.

The G2’s hinge design incorporates adjustable compression settings allowing fine-tuning of seal pressure during installation. This feature enables optimization for different climate conditions and usage patterns. Proper adjustment prevents premature seal wear while ensuring complete weather protection.

G2 hinge replacement requires specialized tools for compression adjustment not needed on other BAKFlip models. These tools ensure proper seal compression and prevent installation errors that compromise performance. Most professional installers stock these tools specifically for G2 service work.

F1 Series Unique Requirements

F1 tonneau covers use the most complex hinge design in the BAKFlip lineup, incorporating integrated water management systems within each hinge assembly. These systems require specialized seals with molded drainage pathways and precise installation procedures to maintain functionality.

F1 hinge seals integrate with the cover’s active drainage system that prevents water accumulation during folding and closing cycles. Standard hinge seals block these drainage pathways and cause water backup leading to leaks and potential cargo damage. Only genuine F1 hinge seals maintain proper drainage function.

Installation complexity increases significantly with F1 covers due to drainage system integration requirements. Professional installation is recommended unless you have extensive mechanical experience and access to specialized tools. Incorrect installation can damage the integrated drainage system requiring expensive repairs.

Diagnosing Hinge Problems Before Replacement

Accurate diagnosis prevents unnecessary bakflip hinge replacement when simpler maintenance resolves operational problems. Many hinge-related issues result from lack of lubrication, dirt accumulation, or minor adjustments rather than component failure requiring replacement.

Water Leak Diagnosis

Water intrusion between panels during closure indicates hinge seal failure requiring replacement. However, verify the leak source by testing with a garden hose while panels remain closed. Water entering through perimeter seals, drain plugs, or damaged panels creates similar symptoms but requires different repairs.

Perform systematic leak testing by isolating each potential entry point during water application. Spray water directly on hinge lines while monitoring for interior drips. True hinge seal failure shows water entry specifically at panel connection points rather than edges or corners.

Document leak locations with photos and measurements for accurate parts ordering. Multiple seal failures suggest UV degradation or age-related deterioration requiring complete hinge seal replacement. Single seal failures might indicate localized damage from cargo impact or installation errors.

Operational Problems

Difficulty folding panels or binding during operation may result from contamination rather than worn components. Clean hinges thoroughly with degreaser and compressed air before assuming component replacement needs. Dirt accumulation often causes operational problems that cleaning resolves completely.

Loose panel connections during transport indicate worn bushings or pins requiring replacement. Test by manually checking panel movement at hinge points with covers closed. Excessive play or movement suggests mechanical wear needing component replacement rather than simple maintenance.

Uneven panel alignment when closed suggests hinge adjustment problems or worn components. Measure panel gaps and alignment carefully to determine if adjustment procedures can correct problems or if component replacement is necessary for proper operation.

Professional vs DIY Installation

Most truck owners can complete bakflip hinge replacement procedures with basic mechanical skills and common hand tools. However, the complexity and precision required for proper installation makes professional service worth considering for many situations.

DIY Installation Advantages

Completing your own hinge replacement saves $200-400 in labor costs compared to professional installation. Most replacement procedures require 2-4 hours using basic socket wrenches, screwdrivers, and cleaning supplies available in most garages. The experience also provides valuable knowledge for future maintenance and troubleshooting.

DIY installation allows you to work at your own pace without appointment scheduling or vehicle downtime at service facilities. You can order parts when convenient and complete work during available free time. This flexibility particularly benefits truck owners with demanding work schedules or limited service facility access.

Hands-on experience with your tonneau cover’s construction helps with future maintenance and problem diagnosis. Understanding how components connect and function enables better care and early problem detection extending overall system lifespan.

When Professional Installation Makes Sense

Complex installations involving drainage system integration or precision adjustments benefit from professional expertise. Technicians experienced with BAKFlip systems complete installations faster and more accurately than first-time DIY attempts. Professional installation also includes warranties on labor and proper operation.

If you lack adequate workspace, proper tools, or mechanical experience, professional service prevents expensive mistakes. Incorrect installation can damage expensive components, void warranty coverage, or create safety hazards. Professional installation costs less than repairing DIY installation errors.

Multiple component failures or comprehensive system rebuilds often justify professional service due to complexity and time requirements. Technicians complete major rebuilds in half the time required for DIY approaches while ensuring proper assembly sequence and adjustments.

Sourcing Genuine Hinge Replacement Parts

Finding authentic BAK Industries hinge components ensures proper fit, warranty compliance, and long-term performance. Multiple sources exist with varying advantages in pricing, availability, and technical support.

Authorized BAK Dealers

BAK Industries maintains an extensive dealer network stocking genuine replacement components with immediate availability for common items. Dealers provide technical support for parts identification and installation guidance. Many offer installation services and warranty support for purchased components.

Use BAK’s dealer locator to find nearby authorized retailers carrying hinge replacement parts. Call ahead to verify specific part availability and avoid unnecessary trips. Dealers can special-order uncommon components with expedited shipping through wholesale accounts.

Many dealers provide package pricing for multiple components when completing comprehensive hinge system rebuilds. This approach saves money compared to individual part purchases while ensuring you have all necessary components for complete restoration.

Online Retailers and Direct Sources

Amazon, RealTruck, and AutoAnything sell genuine BAKFlip hinge replacement components with competitive pricing and fast shipping options. Verify seller authorization and read customer reviews for parts verification and installation experiences. Online ordering works well when you know exact part numbers and specifications.

BAK Industries sells parts directly through their customer service department for guaranteed authenticity and technical support. Direct ordering ensures you receive correct components while supporting continued product development and warranty coverage.

Compare pricing across multiple sources but consider shipping costs and delivery timeframes in total cost calculations. Free shipping thresholds often make ordering multiple components together more economical than separate purchases.

Maintenance Between Replacements

Proper maintenance extends hinge component lifespan significantly and reduces replacement frequency. Simple care routines prevent premature wear while maintaining optimal performance through years of service.

Regular Cleaning and Lubrication

Clean hinge assemblies every three months with compressed air and degreaser to remove accumulated dirt and debris. Contamination accelerates component wear and causes operational problems that cleaning easily prevents. Focus on pivot points, seal contact surfaces, and drainage pathways.

Apply silicone spray to rubber hinge seals quarterly to maintain flexibility and prevent cracking from UV exposure. Avoid petroleum-based products that degrade rubber compounds and accelerate seal deterioration. Light coating maintains seal condition without attracting dirt accumulation.

Lubricate pivot pins and bushings twice yearly with marine-grade grease designed for harsh environmental conditions. This prevents corrosion and reduces friction during folding cycles. Clean excess lubricant that attracts contamination and accelerates component wear.

Inspection and Early Problem Detection

Inspect hinge seals monthly for cracking, hardening, or compression loss indicating approaching replacement needs. Early detection prevents sudden failures and water damage to cargo. Document problem areas with photos for parts ordering and installation planning.

Test panel folding operation weekly to detect binding or resistance changes suggesting contamination or component wear. Address operational problems immediately to prevent accelerated wear and more extensive repairs. Simple maintenance often resolves minor problems before major intervention becomes necessary.

Check hinge alignment quarterly by measuring panel gaps and closure uniformity. Gradually changing alignment suggests component wear or adjustment needs. Early intervention prevents operational problems and extends component service life.

Frequently Asked Questions

How often do BAKFlip hinge seals need replacement?

Most bakflip hinge seal replacement occurs every 5-7 years under normal use conditions. Harsh climates with intense UV exposure or extreme temperature cycling may require replacement sooner. Regular maintenance and protection from UV rays extends seal lifespan significantly.

Can I replace just one hinge seal or should I do all of them?

While single seal replacement is possible, replacing all hinge seals simultaneously ensures uniform protection and prevents repeated disassembly for additional failures. Seals age similarly, so multiple failures often occur within months of each other.

What tools do I need for bakflip hinge replacement?

Basic socket wrench set, screwdrivers, rubber mallet, and cleaning supplies handle most hinge replacement procedures. Add a torque wrench for proper hardware tightening and compressed air for thorough cleaning. No specialized tools required for standard seal replacement.

Will using aftermarket hinge seals void my warranty?

Yes, non-genuine BAK Industries parts void warranty coverage. If other components fail and BAK discovers aftermarket parts during inspection, they can deny warranty claims. Genuine parts cost slightly more but maintain warranty protection for expensive components.

How do I know if my hinge pins need replacement?

Inspect pins for visible scoring, wear marks, or dimensional changes indicating replacement needs. Operational symptoms include binding during folding, loose panel connections, or uneven wear patterns. Replace pins when visual inspection shows damage or operational problems develop.

Can I drive with damaged hinge seals?

Driving with failed hinge seals allows water intrusion and cargo damage but doesn’t create immediate safety hazards. However, continued use may accelerate other component failures and increase repair costs. Address hinge seal problems promptly to maintain weather protection.

Do different BAKFlip models use the same hinge seals?

No, hinge seals are model-specific with different designs for MX4, G2, and F1 covers. Each model requires specific seals engineered for its unique compression requirements and drainage integration. Always verify part numbers for your specific model before ordering.

How long does professional hinge replacement take?

Experienced technicians complete standard hinge seal replacement in 2-3 hours including testing and adjustment. Complex installations involving multiple components may take 4-6 hours. Schedule accordingly and verify completion timeframes when booking service appointments.