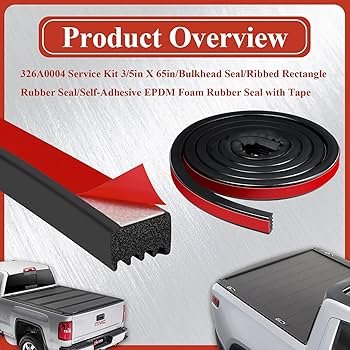

BAKFlip Replacement Seals | Complete Weatherproofing Guide

BAKFlip MX4 Perimeter Seal Kit

Part BAK-356A0015 provides complete perimeter weatherproofing for all MX4 tonneau covers. Premium EPDM rubber construction maintains flexibility from -40°F to 180°F while resisting UV degradation for 5-7 years. Pre-cut lengths eliminate measuring errors and ensure perfect fitment on 5.5ft, 6.5ft, and 8ft truck beds. Self-adhesive backing simplifies installation—clean rails, peel paper, apply seal. Creates continuous compression barrier preventing water, snow, and dust intrusion. Essential replacement when existing seals harden, crack, or lose compression effectiveness.

BAKFlip Hinge Seal Replacement Set

Part BAK-356A0018 includes three flexible hinge seals preventing water intrusion between folding panels. Advanced EPDM compound maintains sealing compression through thousands of fold cycles without permanent deformation. Specifically engineered for MX4, G2, and F1 models with precise groove dimensions matching hinge channels. Installation requires partial panel separation to access hinge connections—moderate difficulty but achievable with basic tools. Replace every 5-7 years or when water penetrates between panels while perimeter sealing remains intact. Critical for maintaining weatherproof cargo protection.

BAKFlip G2 Rubber Seal Kit

Part BAK-226A0012 complete seal system for G2 tonneau covers includes perimeter seals and gaskets. Ozone-resistant rubber formulation withstands environmental exposure without hardening or cracking. Designed specifically for G2’s unique rail system with exact compression requirements for proper weather sealing. Easy peel-and-stick installation takes 30 minutes with thorough surface preparation. Compatible with all G2 truck applications including Ford F-150, Chevy Silverado, Ram 1500, and Toyota Tundra. Maintains warranty compliance when genuine BAK Industries seals replace worn components. Essential maintenance item every 4-6 years depending on climate exposure.

BAKFlip Drain Tube Seal Assembly

Part BAK-226A0025 prevents water intrusion through side rail drainage systems. Small but critical components that seal drain tube connections preventing moisture from bypassing perimeter sealing. High-grade silicone construction resists temperature extremes and chemical exposure from road salt and cleaning products. Quick replacement requires removing drain tubes, installing new seals, and reassembling connections. Often overlooked during routine maintenance but essential for complete weather protection. Replace whenever drain tubes are serviced or if mysterious water intrusion occurs despite good perimeter sealing. Compatible across multiple BAKFlip tonneau cover models.

Understanding BAKFlip Replacement Seals

The sophisticated sealing system of your BAKFlip tonneau cover represents one of its most critical features, yet these vital components remain largely invisible until they fail. Unlike simple foam strips found on budget covers, BAKFlip replacement seals utilize advanced materials and precision engineering to create multiple barriers against water, dust, and temperature intrusion.

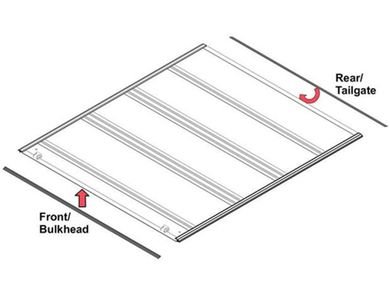

Your tonneau cover employs a multi-layer sealing strategy with perimeter seals creating the primary weather barrier, hinge seals preventing panel-to-panel leaks, and specialized gaskets sealing drainage systems. This comprehensive approach explains why BAKFlip covers maintain superior weatherproofing compared to competitors—every potential leak path receives dedicated sealing attention.

The materials science behind these seals goes far beyond basic rubber strips. EPDM (Ethylene Propylene Diene Monomer) rubber provides exceptional resistance to ozone, UV radiation, and temperature extremes while maintaining flexibility through years of compression cycling. This advanced compound costs more than basic rubber but delivers the long-term performance that justifies BAKFlip’s premium positioning.

Each seal design reflects specific engineering requirements for its location and function. Perimeter seals feature hollow chambers that compress evenly under panel weight while recovering shape when panels open. Hinge seals incorporate flexible ribs that maintain contact during folding motion without binding or tearing. Drain seals use solid construction for permanent compression in static applications.

The Science of Weatherproof Sealing

Effective weatherproofing demands more than simply stuffing rubber into gaps. BAKFlip replacement seals create controlled compression zones that maintain consistent contact pressure across varying temperatures and panel positions. Too little compression allows leaks; too much compression causes premature seal failure from over-stress.

Temperature cycling presents the greatest challenge for seal longevity. Summer heat expands materials while winter cold contracts them—this constant movement gradually fatigues rubber compounds. Premium EPDM formulations resist this degradation far longer than cheaper alternatives, explaining why genuine BAKFlip seals last 5-7 years versus 2-3 years for aftermarket options.

The adhesive systems bonding seals to aluminum rails must withstand similar temperature extremes plus mechanical stress from panel operation. Structural adhesives used on genuine seals maintain bond strength through thousands of temperature cycles while cheaper alternatives fail within months, causing seal displacement and immediate leakage.

BAKFlip Hinge Seal Replacement Process

Replacing BAKFlip hinge seals requires more mechanical skill than perimeter seal replacement but remains achievable for experienced DIY mechanics. The process involves partial panel separation to access hinge channels—a delicate operation requiring careful attention to panel alignment during reassembly.

Begin by fully opening the tonneau cover and identifying which panels require hinge seal replacement. Water stains between specific panels indicate localized seal failure while general wetness suggests multiple seal replacement needs. Document panel positions with photos before disassembly to ensure correct realignment.

Each hinge connection uses specific hardware arrangements that must be reinstalled identically. Hardware orientation matters—reversed bolts or washers can prevent proper panel alignment or damage new seals during installation. Use magnetic parts trays to organize hardware by removal sequence for systematic reassembly.

Tools and Materials Required

Successful BAKFlip hinge seal replacement requires socket wrenches, flat-blade screwdrivers, cleaning supplies, and replacement seals. A torque wrench ensures proper hardware tightening without over-stressing aluminum components. Isopropyl alcohol removes old adhesive residue and prepares surfaces for optimal new seal adhesion.

Replacement seals arrive with protective paper covering adhesive surfaces. Remove this paper only immediately before installation—exposed adhesive attracts dirt and loses bonding strength. Work in sections rather than exposing all adhesive surfaces simultaneously.

Consider replacing related hardware during hinge seal service. Bolts, washers, and clips subjected to years of weather exposure may show corrosion or wear. New hardware ensures reliable connections and prevents future problems requiring repeat disassembly.

Installation Sequence

Start hinge seal replacement with the tailgate-adjacent panel and work toward the cab. This sequence maintains cover stability during the process and allows testing of each repair before proceeding. Complete one hinge connection entirely before starting the next—partial assemblies create confusion and increase error risk.

Clean hinge channels thoroughly before installing new seals. Old seal residue prevents proper new seal seating and creates uneven compression. Use plastic scrapers to avoid scratching aluminum surfaces—metal tools leave gouges that compromise sealing effectiveness.

New seals must seat completely in hinge channels without gaps or overlaps. Verify seal positioning before final hardware tightening. Misaligned seals bind during panel operation and tear within weeks. Take time for precise positioning—rushing this step guarantees premature failure.

BAKFlip MX4 Seal Replacement Specifics

The BAKFlip MX4 employs the most advanced sealing system in the BAKFlip lineup with enhanced perimeter seals and upgraded hinge designs. Understanding MX4-specific seal characteristics ensures proper replacement part selection and installation procedures.

BAKFlip MX4 seal replacement differs from earlier models in several key areas. The perimeter seals feature improved hollow chamber designs that compress more evenly under load while recovering shape faster when panels open. This enhanced geometry extends seal life by reducing stress concentration points that cause premature cracking.

MX4 hinge seals incorporate flexible lip extensions that maintain contact during panel articulation without binding mechanisms. These delicate features require careful handling during installation—rough treatment tears lip seals rendering them ineffective immediately.

Generation Differences

MX4 Generation 2 and Generation 3 models use slightly different seal configurations despite visual similarities. Gen 3 seals feature enhanced UV resistance and improved compression recovery characteristics developed through years of field testing and customer feedback.

Most Gen 2 and Gen 3 seals interchange functionally, but using current-generation parts provides improved performance. When replacing worn seals on older covers, consider upgrading to latest-generation components for extended service life and better weather protection.

Verify your MX4 generation before ordering replacement seals. Serial numbers and purchase dates help identify which generation you own. Gen 3 models shipped starting mid-2021 and feature subtle design improvements visible upon close inspection.

MX4 Installation Considerations

The MX4’s aluminum construction requires specific torque specifications during seal replacement to prevent component damage. Over-tightening can crack rails while under-tightening allows movement that compromises sealing effectiveness. Follow BAK Industries torque recommendations precisely.

MX4 drainage systems integrate closely with sealing components, making drain tube seal replacement essential during perimeter seal service. Old drain seals often fail simultaneously with perimeter seals—replacing both systems together prevents repeat maintenance within months.

Consider complete seal system replacement rather than individual component replacement when multiple seals show wear. The labor involved in accessing sealing systems makes comprehensive replacement more cost-effective than multiple service sessions.

Rubber Seal Replacement for Different Models

Each BAKFlip model uses specific tonneau cover rubber seal replacements engineered for that cover’s construction and operating characteristics. Understanding model-specific requirements prevents ordering incorrect parts and ensures optimal performance after replacement.

The BAKFlip G2 uses simpler sealing systems than the MX4 but achieves excellent weather protection through proven designs. G2 seals emphasize durability and ease of replacement over advanced features. This makes G2 seal replacement more straightforward for DIY mechanics while maintaining reliable weatherproofing.

BAKFlip F1 models employ lightweight sealing solutions optimized for the F1’s fiberglass construction. These seals must accommodate different expansion rates between fiberglass panels and aluminum rails while maintaining effective compression over varying temperatures.

Cross-Model Compatibility

Some BAKFlip replacement seals work across multiple models while others remain model-specific. Perimeter seals often interchange between models sharing similar rail designs. Hinge seals typically require model-specific parts due to unique panel connection geometries.

Attempting to use incorrect seals creates immediate problems. Wrong seal dimensions either fail to seal properly or bind mechanisms preventing normal operation. Always verify part numbers match your specific cover model and generation rather than assuming compatibility.

When genuine parts aren’t immediately available, authorized dealers can cross-reference alternative parts that provide temporary solutions. However, these substitutions should be temporary measures until correct parts arrive—long-term use of incorrect seals compromises performance and may void warranty coverage.

Universal vs Model-Specific Seals

Some aftermarket suppliers offer “universal” tonneau cover rubber seal replacements claiming to fit multiple brands and models. These generic solutions rarely provide the precise fit and performance characteristics of genuine BAKFlip seals engineered for specific applications.

Universal seals typically use one-size-fits-all approaches that compromise effectiveness. They may be too hard for proper compression, too soft for durability, or incorrectly shaped for optimal sealing contact. The modest cost savings evaporate when premature replacement becomes necessary.

Stick with genuine BAKFlip replacement seals for applications where weatherproofing matters. The engineering investment in model-specific designs delivers superior long-term value compared to generic alternatives that seem economical initially but fail prematurely.

Signs Your BAKFlip Seals Need Replacement

Recognizing early warning signs of seal failure allows proactive BAKFlip replacement seals installation before water damage occurs to cargo or truck bed components. Most seal degradation happens gradually, making regular inspection essential for timely replacement.

Water intrusion represents the most obvious sign of seal failure, but different leak patterns indicate specific seal problems. Water pooling around perimeter edges suggests perimeter seal replacement needs while moisture between panels indicates hinge seal failure. Systematic leak diagnosis prevents unnecessary replacement of functional seals.

Visual inspection reveals seal condition before leakage occurs. Healthy seals appear uniformly black with smooth surfaces and springy texture. Degraded seals show cracking, hardening, permanent compression marks, or color fading from black to gray or brown.

Performance-Based Indicators

Changes in panel closing effort often signal seal degradation before visible damage appears. Seals losing flexibility require increasing force for proper compression. Conversely, seals compressing too easily indicate material breakdown and imminent sealing failure.

Wind noise while driving with the cover closed suggests air leaks through compromised seals. Fresh seals create complete barriers preventing air infiltration. Degraded seals allow air movement that generates whistling or rushing sounds at highway speeds.

Dust accumulation in closed truck beds indicates seal compromise allowing fine particle intrusion. Effective seals block dust infiltration completely. Finding dust layers after highway driving means immediate seal inspection and likely replacement needs.

Seasonal Inspection Schedule

Inspect BAKFlip replacement seals twice yearly during spring and fall maintenance routines. Spring inspections reveal winter freeze-thaw damage while fall inspections identify summer UV degradation before harsh weather arrives.

Pay special attention to seal corners and joints where stress concentration accelerates wear. These high-stress areas fail first and indicate overall seal condition. Cracking at corners suggests system-wide replacement needs rather than localized repairs.

Document inspection findings with photos showing seal condition over time. Progressive degradation becomes apparent when comparing photos from multiple inspection periods. This documentation helps predict replacement timing and validates warranty claims if premature failure occurs.

Professional Installation vs DIY Replacement

Deciding between professional installation and DIY BAKFlip replacement seals replacement depends on your mechanical skills, available tools, and time constraints. Simple perimeter seal replacement suits most DIY mechanics while complex hinge seal replacement benefits from professional expertise.

Professional installation ensures correct procedures, proper torque specifications, and warranty compliance. Experienced technicians complete installations quickly without risk of component damage from inexperienced handling. They also identify related problems requiring attention during seal replacement.

DIY installation saves labor costs and provides valuable learning experience about your tonneau cover’s construction and operation. However, mistakes during installation can damage expensive components or create immediate leakage requiring professional correction at additional cost.

Cost-Benefit Analysis

Professional BAKFlip seal replacement typically costs $150-300 in labor depending on seal complexity and local rates. Simple perimeter seal installation runs toward the lower end while complete hinge seal replacement approaches higher costs due to increased labor time.

DIY installation eliminates labor costs but requires tool investment and time commitment. Basic hand tools suffice for simple replacements, but complex jobs may require specialized equipment purchase exceeding professional installation costs.

Consider your experience level honestly. Simple seal replacement makes excellent DIY projects for mechanically inclined owners. Complex procedures involving panel separation and precise alignment benefit from professional expertise preventing costly mistakes.

When Professional Installation Makes Sense

Multiple seal system replacement, warranty work, or concurrent repairs justify professional installation costs. Technicians handle comprehensive jobs efficiently while ensuring all systems function correctly upon completion.

If you lack mechanical experience, proper tools, or adequate workspace, professional installation delivers better results with less frustration. The modest additional cost prevents potential problems from inexperienced attempts at complex procedures.

Professional installation also makes sense when time constraints prevent thorough DIY work. Rushed installations create problems requiring expensive corrections. Better to invest in professional service than compromise results trying to save money.

Maintenance Tips for Extended Seal Life

Proper maintenance significantly extends BAKFlip replacement seals service life, reducing replacement frequency and maintaining optimal weather protection. Simple care routines prevent premature degradation and identify problems before they require expensive repairs.

Regular cleaning removes corrosive substances that accelerate seal degradation. Road salt, industrial pollution, and organic debris attack rubber compounds causing premature cracking and hardening. Monthly washing with mild soap eliminates these threats while allowing inspection for developing problems.

Apply silicone protectant to clean seals every three months to maintain flexibility and UV resistance. Quality protectants penetrate rubber compounds restoring suppleness while providing surface protection against environmental damage. Avoid petroleum-based products that cause rubber swelling and accelerated failure.

Environmental Protection

Park in shaded areas when possible to reduce UV exposure that breaks down rubber compounds over time. Consistent shade parking can double seal life in sunny climates. When shade isn’t available, consider tonneau cover protectants with enhanced UV blocking properties.

Temperature extreme protection involves avoiding unnecessary thermal cycling. Don’t operate covers when panels are ice-covered or extremely hot from sun exposure. Allow temperature moderation before manipulation to prevent thermal shock damage to seals and mechanisms.

Remove snow and ice accumulation promptly to prevent prolonged compression that causes permanent seal deformation. Use plastic tools for ice removal to avoid cutting seals with metal scrapers. Compressed air effectively removes debris from seal channels without damage risk.

Operational Best Practices

Operate your tonneau cover gently and deliberately to minimize seal stress. Slamming panels creates shock loads that accelerate wear while gradual operation allows seals to compress and decompress naturally. This operating style extends seal life significantly.

Ensure proper panel alignment during closing to prevent seal binding and tearing. Misaligned panels create uneven compression that concentrates stress in small areas. Take time for correct alignment rather than forcing panels into position through brute force.

Keep cargo away from seals to prevent damage from sharp edges or excessive weight. Heavy items can over-compress seals causing permanent deformation. Sharp objects can cut seals requiring immediate replacement. Plan cargo placement to protect sealing systems.

Frequently Asked Questions

How often should I replace BAKFlip replacement seals?

Most BAKFlip replacement seals last 5-7 years with proper maintenance and normal use conditions. Climate factors significantly affect lifespan—seals in sunny, hot climates may need replacement sooner than those in temperate regions. Inspect seals twice yearly and replace when they show cracking, hardening, or persistent compression marks.

Can I use aftermarket seals instead of genuine BAKFlip parts?

While aftermarket options exist, genuine BAKFlip seals provide superior fit, materials, and longevity. Generic seals often use inferior rubber compounds that fail prematurely. More critically, non-genuine parts can void your warranty coverage, potentially costing hundreds in denied claims for unrelated failures.

What’s the difference between perimeter and hinge seal replacement?

Perimeter seals create weather barriers around the cover’s outer edges and typically use self-adhesive installation requiring basic cleaning and positioning skills. Hinge seals prevent water intrusion between panels and require partial cover disassembly for access—a more complex procedure needing mechanical experience.

Do I need special tools for BAKFlip seal replacement?

Basic perimeter seal replacement requires only cleaning supplies and careful positioning. Hinge seal replacement needs socket wrenches, screwdrivers, and a torque wrench for proper hardware installation. Most truck owners already possess these tools, making DIY replacement feasible for simple seal systems.

Will seal replacement restore my cover’s original weather protection?

Yes, installing genuine BAKFlip replacement seals restores factory-level weather protection when properly installed on covers with good structural integrity. New seals eliminate the most common source of water intrusion—degraded rubber components—returning your cover to like-new performance.

Can I replace just one section of sealing or must I do complete replacement?

You can replace individual seal sections if damage is localized and other seals remain in good condition. However, seals typically degrade at similar rates, making partial replacement a temporary solution. Complete system replacement often proves more cost-effective long-term by eliminating multiple service appointments.

How do I determine which seal is causing water leaks?

Systematic testing helps identify failed seals. Perimeter leaks show water around cover edges while hinge leaks appear between panels. Use a garden hose to spray specific areas while observing from inside the truck bed. This targeted testing pinpoints exact failure locations for efficient repair.

Are BAKFlip seals covered under warranty?

BAKFlip covers include 5-year limited warranty covering manufacturing defects in seals. Normal wear, UV degradation, and damage from misuse aren’t covered. Premature seal failure from material defects within the warranty period typically qualifies for free replacement parts, though labor costs remain your responsibility.