BAKFlip Tailgate Seal | Replacement Seals & Weather Protection

BAKFlip MX4 Tailgate Seal Kit

Part BAK-356A0022 provides complete tailgate perimeter sealing with premium EPDM rubber construction. Pre-cut to exact tailgate dimensions for Ford F-150, Chevrolet Silverado, RAM 1500, and Toyota Tundra applications. Self-adhesive backing ensures permanent installation without additional fasteners or clamps. Maintains flexibility through temperature extremes from -40°F to 200°F without cracking or hardening. Creates weatherproof barrier preventing rain, snow, dust, and debris infiltration. Replace every 5-7 years for optimal performance.

BAKFlip G2 Universal Tailgate Seal

Part BAK-355A0018 fits all G2 tonneau cover models with cut-to-length flexibility for custom applications. Industrial-grade EPDM rubber compound resists UV degradation and ozone cracking for extended service life. Dual-density construction provides firm attachment base with soft sealing surface for complete weather protection. Compatible with aftermarket tailgate components including bed extenders and cargo management systems. Installation requires basic surface preparation and takes 30 minutes with included instructions.

BAKFlip Tailgate Seal Installation Kit

Complete installation package includes surface cleaner, adhesion primer, and installation tools for professional-quality results. Isopropyl-based cleaner removes oils, wax, and contaminants that prevent proper seal adhesion. Primer creates chemical bond between rubber and painted tailgate surfaces. Installation roller ensures even pressure application eliminating air bubbles and gaps. Works with all BAKFlip tailgate seal applications regardless of truck make or model. Essential for achieving manufacturer warranty compliance.

BAKFlip F1 Heavy-Duty Tailgate Seal

Part BAK-354A0012 engineered for commercial and heavy-use applications requiring maximum durability. Reinforced EPDM construction with integrated steel reinforcement strips prevents tearing under extreme stress. Enhanced thickness provides superior compression recovery and maintains sealing integrity through thousands of open-close cycles. Chemical-resistant formulation withstands exposure to hydraulic fluids, diesel fuel, and industrial cleaning solvents. Ideal for work trucks, fleet vehicles, and construction applications where standard seals fail prematurely.

Understanding BAKFlip Tailgate Seal Function

The BAKFlip tailgate seal serves as the critical barrier between your tonneau cover’s rear panel and the truck’s tailgate, preventing water, dust, and debris infiltration that compromises cargo protection. Unlike generic truck bed seals designed for broad compatibility, BAKFlip tailgate seals feature precise engineering for each cover model’s specific closing mechanism and panel thickness requirements.

When your BAKFlip MX4 tonneau cover closes, the rear panel compresses the tailgate seal creating an airtight barrier. This compression must be perfectly calibrated—too soft and water penetrates, too firm and panels won’t close properly or seals tear from excessive force. BAK Industries engineers each tailgate seal compound for optimal compression characteristics matching each model’s closing force and panel weight.

The seal also accommodates truck manufacturing tolerances that affect tailgate alignment and panel fit. Ford F-150 tailgates sit differently than Chevrolet Silverado or RAM 1500 configurations. BAKFlip tailgate seals compensate for these variations ensuring consistent weather protection regardless of your truck’s specific dimensions or tolerances.

Why Generic Seals Fail

Aftermarket “universal” tailgate seals promise compatibility across multiple tonneau cover brands but deliver compromised performance on BAKFlip systems. These generic seals use one-size-fits-all rubber compounds that either compress too easily allowing water penetration or resist compression preventing proper panel closure.

Generic seals also lack the precise dimensional accuracy of genuine BAKFlip components. They’re designed for “close enough” fitment rather than exact specifications. This results in gaps at corners, uneven compression along the seal length, and premature wear from improper loading patterns.

The adhesive systems on aftermarket seals often fail within months of installation. Cheap adhesives don’t create permanent bonds with painted tailgate surfaces, allowing seals to peel away during normal operation. You’ll find yourself repeatedly pressing loose seal sections back into place—a clear sign of inferior adhesive chemistry.

Signs Your BAKFlip Tailgate Seal Needs Replacement

Recognizing early warning signs of tailgate seal deterioration prevents water damage to cargo and maintains your tonneau cover’s protective function. Most owners notice water leaks before identifying the specific failure point, but understanding seal-specific symptoms helps target repairs precisely.

Water Intrusion Patterns

Water entering through a failed BAKFlip tailgate seal follows predictable patterns different from other seal failures. Tailgate seal leaks typically manifest as water pooling at the rear of the bed near the tailgate, especially after rain or washing. You might notice water marks on cargo stored against the tailgate or moisture accumulation in rear bed corners.

During heavy rain, observe whether water drips from the rear panel-tailgate junction when opening the cover. Healthy seals redirect water around the seal perimeter through integrated drainage channels. Failed seals allow direct water penetration creating visible drips and puddles.

Check for water intrusion after car washes or pressure washing. If water appears inside the bed despite proper panel closure, the tailgate seal likely needs replacement. This test eliminates other potential leak sources by focusing on rear panel sealing specifically.

Visual Inspection Indicators

Examine your BAKFlip tailgate seal quarterly for visible deterioration signs. Healthy EPDM rubber appears uniformly black with consistent flexibility along the entire length. Sections that appear gray, cracked, or brittle indicate UV degradation requiring replacement.

Look for compression set—areas where repeated panel closure has permanently flattened the seal. Healthy seals bounce back to original shape when panels open. Permanently compressed sections can’t create proper weather barriers and allow water penetration even when panels close completely.

Check adhesion by gently pulling seal edges away from the tailgate surface. Seals should feel firmly bonded without lifting or peeling. Loose sections indicate adhesive failure requiring complete seal replacement rather than spot repairs that don’t address underlying adhesion problems.

Performance Degradation

Monitor how much force your BAKFlip panels require for closure. New tailgate seals provide smooth, consistent resistance as panels compress the rubber. Degraded seals either offer no resistance (allowing water leaks) or excessive resistance (indicating hardening that prevents proper closure).

Listen for unusual noises during panel operation. Healthy seals compress silently as panels close. Squeaking, grinding, or scraping sounds suggest seal hardening creating friction between the rubber and panel surfaces. These sounds indicate immediate replacement needs before seals tear completely.

Test panel alignment after closure. Properly functioning tailgate seals help maintain consistent panel positioning by providing uniform compression support. If rear panels sit unevenly or require adjustment for proper alignment, worn seals may no longer provide adequate support structure.

Choosing the Right BAKFlip Tailgate Seal

Selecting the correct tailgate seal requires matching your specific BAKFlip model, truck application, and usage requirements. BAK Industries produces model-specific seals optimized for each tonneau cover’s unique closing mechanism and panel configuration.

Model-Specific Requirements

The BAKFlip MX4 tailgate seal differs from G2 and F1 applications in rubber compound formulation and dimensional specifications. MX4 models use aluminum panels requiring specific compression characteristics that accommodate the lighter panel weight and different closing force compared to heavier fiberglass panels.

BAKFlip G2 models use different tailgate seal configurations accounting for the model’s unique latching system and panel thickness. The G2’s manual locking mechanism creates different compression patterns requiring tailored seal geometry for optimal weather protection.

F1 tonneau covers employ heavy-duty seal compounds designed for commercial applications and high-cycle usage. These seals resist tearing and compression set better than residential-grade compounds but may feel stiffer during normal operation.

Truck-Specific Considerations

Ford F-150 applications require tailgate seals accommodating the model’s specific tailgate design and closure mechanisms. F-150 tailgates feature unique geometry that affects how tonneau cover panels align and compress sealing surfaces. BAKFlip provides F-150-specific part numbers ensuring proper fit.

Chevrolet Silverado and GMC Sierra trucks share similar tailgate configurations but differ from Ford applications. The Silverado tailgate seal applications account for different panel gaps and closure force requirements. Using F-150 seals on Silverado applications results in poor fit and compromised weather protection.

RAM 1500 trucks feature distinct tailgate designs requiring specific seal configurations. The RAM’s tailgate geometry affects how BAKFlip panels close and compress against sealing surfaces. RAM-specific tailgate seals ensure proper compression and weather barrier formation.

Usage-Based Selection

Commercial and high-mileage applications benefit from heavy-duty tailgate seal compounds that resist accelerated wear from frequent opening and closing cycles. Construction workers, delivery drivers, and contractors should specify commercial-grade seals lasting longer under demanding conditions.

Recreational users operating covers weekly rather than daily can use standard residential-grade seals providing excellent weather protection with normal lifespan expectations. These seals offer optimal comfort and ease of operation for typical truck owner usage patterns.

Extreme climate applications may require specialized rubber compounds formulated for specific temperature ranges or chemical exposure. Desert environments with extreme UV exposure benefit from enhanced UV-resistant formulations. Cold climate applications need compounds maintaining flexibility at sub-zero temperatures.

BAKFlip Tailgate Seal Installation Process

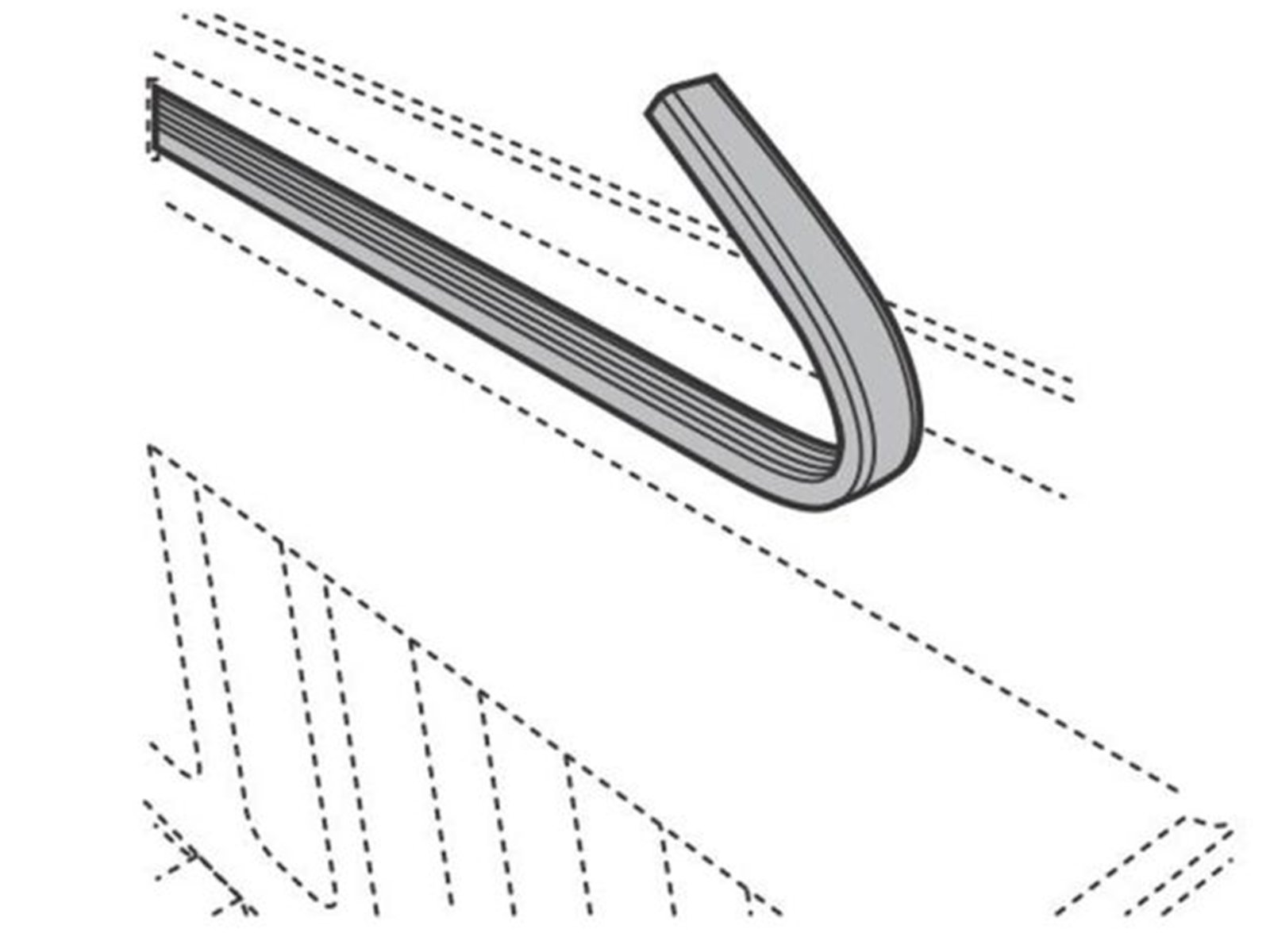

Proper BAKFlip tailgate seal installation ensures maximum weather protection and component longevity. The process requires careful surface preparation, precise alignment, and correct adhesive activation for permanent bonding between seal and tailgate surfaces.

Surface Preparation Requirements

Begin installation by thoroughly cleaning the tailgate surface where the new seal will attach. Remove all traces of the old seal, adhesive residue, wax, and contaminants using isopropyl alcohol or specialized adhesive cleaner. Any remaining residue prevents proper bonding and causes premature seal failure.

Inspect the tailgate surface for paint damage, rust, or dents that affect seal adhesion. Minor imperfections don’t prevent installation, but significant damage should be repaired before seal installation. Smooth any rough areas with fine sandpaper to create consistent bonding surfaces.

Allow the cleaned surface to dry completely before applying primer or installing the new seal. Moisture trapped under seals prevents adhesive bonding and creates corrosion issues over time. Wait at least 30 minutes after cleaning before proceeding with installation.

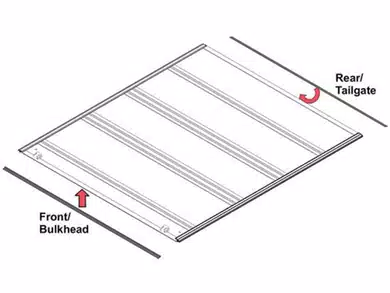

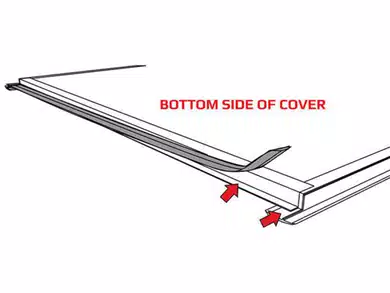

Alignment and Positioning

Mark the correct seal placement using the old seal as a template or following BAKFlip’s installation diagrams. Proper positioning ensures even compression when panels close and maintains consistent gaps around the entire perimeter. Misaligned seals create high-stress areas that fail prematurely.

Start seal installation at the center of the tailgate working toward the corners. This technique prevents accumulated positioning errors that occur when starting at corners. Center-out installation distributes any dimensional variations evenly rather than concentrating them at one location.

Check panel closure alignment during installation by test-fitting periodically. The new seal should allow smooth panel operation without binding or excessive force. If panels don’t close properly, remove and reposition the seal before the adhesive fully cures.

Adhesive Activation and Curing

Apply steady, even pressure along the entire seal length using the installation roller to eliminate air bubbles and ensure complete adhesive contact. Work systematically to avoid missing sections that create leak paths and weak adhesion points.

Allow the adhesive to cure undisturbed for the manufacturer’s specified time—typically 24-48 hours depending on temperature and humidity conditions. Premature tonneau cover operation can dislodge seals before achieving full bond strength.

Test the installation after full curing by operating the cover normally and checking for proper compression and alignment. The seal should compress evenly without binding or creating resistance during normal operation. Any issues require immediate attention before problems worsen.

Maintenance for Extended Tailgate Seal Life

Regular maintenance extends BAKFlip tailgate seal service life significantly while maintaining optimal weather protection. Simple cleaning and conditioning routines prevent premature degradation and catch problems before they require expensive replacements.

Cleaning Protocol

Clean your tailgate seal monthly with mild soap and water to remove dirt, debris, and contaminants that accelerate rubber degradation. Accumulated grime acts like sandpaper grinding against the seal surface during panel operation. Regular cleaning eliminates these abrasive particles extending seal life.

Avoid petroleum-based cleaners, harsh detergents, or solvents that degrade EPDM rubber compounds. Use automotive soap or mild dish soap with warm water for safe, effective cleaning. Rinse thoroughly and dry completely to prevent water spots and mineral deposits.

Pay special attention to corners and complex curves where debris accumulates. Use soft brushes or cloths to clean intricate areas without damaging the rubber surface. These areas experience highest stress and benefit most from regular maintenance attention.

Conditioning and Protection

Apply silicone-based rubber conditioner every three months to maintain seal flexibility and UV resistance. Quality conditioners penetrate the rubber compound restoring plasticizers lost through normal aging and environmental exposure. This prevents hardening that leads to cracking and compression set.

Avoid armor-all type products containing petroleum distillates that cause rubber swelling and degradation. Use conditioners specifically formulated for EPDM rubber applications. These products enhance flexibility without compromising the rubber’s chemical structure or dimensional stability.

Focus conditioning efforts on areas receiving maximum UV exposure—typically the top surfaces of seals that face skyward when covers are closed. These areas degrade fastest and benefit most from regular conditioning treatments.

Inspection Schedule

Inspect your tailgate seal condition monthly during routine vehicle maintenance. Look for cracking, hardening, compression set, or adhesion failures that indicate developing problems. Early detection allows planned replacement during convenient times rather than emergency repairs.

Test seal compression by gently pressing sections with your finger. Healthy rubber should compress easily and bounce back quickly when released. Sections that stay compressed or feel hard indicate material degradation requiring attention.

Check adhesion integrity by examining seal edges for lifting or separation from the tailgate surface. Address minor adhesion failures immediately with appropriate adhesive to prevent water intrusion and further degradation. Complete replacement becomes necessary if adhesion failures affect large seal sections.

Troubleshooting Common BAKFlip Tailgate Seal Issues

Understanding common BAKFlip tailgate seal problems helps diagnose issues quickly and choose appropriate solutions. Most problems result from installation errors, environmental factors, or normal wear patterns that owners can address with proper knowledge and techniques.

Water Leak Diagnosis

Water leaks through closed tonneau covers often blame the tailgate seal, but other sources can create similar symptoms. Perform systematic leak testing to identify the actual source before replacing seals unnecessarily. Close the cover completely and spray water specifically at the tailgate junction while observing for penetration.

If water enters during tailgate-specific testing, the tailgate seal requires replacement or adjustment. However, water entering from side rails or panel joints indicates different problems requiring specific solutions. Don’t assume all leaks originate from tailgate seal failures.

Consider seasonal factors affecting leak patterns. Cold weather hardens seals reducing their compression and sealing ability. Hot weather can cause thermal expansion creating temporary gaps. Adjust expectations for minor seasonal variations while addressing permanent seal degradation promptly.

Compression Problems

Panels requiring excessive force for closure often indicate tailgate seal hardening from UV exposure or normal aging. Hard seals resist compression creating difficult operation and potential panel damage from excessive closing force. This condition requires immediate seal replacement before panels or latches fail.

Alternatively, panels closing too easily without resistance suggest seal compression set where repeated compression has permanently flattened the rubber. These seals can’t create proper weather barriers and allow water penetration despite apparent closure.

Address compression problems immediately rather than adapting to difficult operation. Continued use with improper compression damages panel edges, latches, and hinge mechanisms creating expensive secondary repairs beyond simple seal replacement.

Adhesion Failures

Seals lifting from tailgate surfaces indicate adhesive system failure requiring complete seal replacement. Attempting to re-adhere lifted sections provides temporary fixes but doesn’t address underlying adhesion chemistry problems. The adhesive system has failed and won’t reliably bond again.

Prevent adhesion failures during installation by ensuring complete surface preparation and proper curing conditions. Contaminated surfaces, insufficient cure time, or extreme temperatures during installation create adhesion problems that manifest months later as lifted seals.

Some adhesion failures result from chemical incompatibility between seal adhesives and tailgate coatings. Bedliner materials, aftermarket paint systems, or protective coatings may prevent proper bonding. Consult BAK Industries for specialized adhesion solutions for non-standard tailgate surfaces.

BAKFlip Tailgate Seal Compatibility Across Models

Understanding BAKFlip model compatibility prevents ordering incorrect seals while identifying upgrade opportunities when replacing worn components. Most BAKFlip models use unique seal specifications, but some universal applications exist across model lines.

MX4 and G2 Compatibility

The BAKFlip MX4 tailgate seal differs from G2 applications in rubber compound and dimensional specifications. MX4 aluminum construction requires different compression characteristics than G2 fiberglass panels. Using incorrect seals results in poor weather protection and difficult operation.

Some universal seal applications work across both model lines for specific truck applications. However, model-specific seals always provide superior performance compared to universal alternatives. When replacement time arrives, specify exact model compatibility rather than accepting “close enough” universal options.

Check your tonneau cover’s documentation or contact BAK Industries to verify which model you own before ordering seals. Visual identification can be difficult, and using incorrect seals creates performance problems and potential warranty issues.

F1 Heavy-Duty Applications

BAKFlip F1 models use heavy-duty tailgate seals designed for commercial applications and high-cycle usage. These seals work on other BAKFlip models but may feel stiffer during operation due to enhanced durability compounds.

Consider F1 seals for recreational applications experiencing premature wear from frequent use or harsh conditions. The enhanced durability justifies slightly stiffer operation for users prioritizing longevity over ultimate comfort.

F1 seals cost more than standard applications but provide significantly extended service life under demanding conditions. Calculate replacement frequency to determine whether heavy-duty seals provide better value despite higher initial cost.

Truck-Specific Variations

Ford F-150, Chevrolet Silverado, RAM 1500, and Toyota Tundra applications may use different tailgate seal configurations even within the same BAKFlip model. Truck manufacturers’ tailgate designs affect seal requirements necessitating vehicle-specific part numbers.

Always verify truck compatibility when ordering replacement seals. Part numbers include truck-specific designations ensuring proper fit and function. Generic “fits all trucks” seals compromise performance compared to vehicle-specific applications.

Some aftermarket tailgate modifications like bed extenders or cargo management systems require specialized seal configurations. Consult BAK Industries for compatibility guidance when non-standard tailgate components are installed.

Frequently Asked Questions

How often should I replace my BAKFlip tailgate seal?

Replace your BAKFlip tailgate seal every 5-7 years under normal conditions, or sooner if you notice water leaks, cracking, or hardening. Extreme climates and frequent use may require more frequent replacement. Regular inspection helps identify replacement needs before complete failure occurs.

Can I use MX4 tailgate seals on a G2 model?

No, MX4 and G2 models require different tailgate seal specifications. The aluminum MX4 panels have different compression requirements than G2 fiberglass construction. Using incorrect seals results in poor fit, difficult operation, and compromised weather protection. Always use model-specific seals for optimal performance.

What tools do I need for tailgate seal installation?

Basic installation requires cleaning supplies, adhesive remover, and installation roller. Use isopropyl alcohol for surface cleaning, plastic scrapers for old seal removal, and a rubber roller for proper adhesion. No specialized tools are needed—most installations take 30-45 minutes with basic hand tools.

Why is my new tailgate seal causing difficult panel closure?

New seals may feel stiff initially but should break in within the first week of use. If panels remain difficult to close, the seal may be incorrectly positioned or incompatible with your model. Check installation alignment and verify you ordered the correct part number for your specific truck and cover model.

Can I repair a torn tailgate seal instead of replacing it?

Small tears sometimes accept temporary repair with rubber cement or seal patches, but complete replacement provides reliable long-term solutions. Repaired seals rarely achieve original weather protection levels and often fail again within months. Replacement costs justify the permanent solution over repeated repair attempts.

Do aftermarket tailgate seals work with BAKFlip covers?

While some aftermarket seals claim BAKFlip compatibility, genuine BAK Industries seals provide superior fit and performance. Generic seals use different rubber compounds and dimensions that compromise weather protection. They may also void warranty coverage if component failures occur.

How do I know which generation BAKFlip I have?

Check your purchase documentation or serial number to determine your BAKFlip generation. Contact BAK Industries customer service with your serial number for definitive identification. Some seals interchange between generations, but model-specific seals always provide optimal performance.

Can extreme weather damage tailgate seals?

Extreme heat, cold, and UV exposure accelerate normal seal degradation but rarely cause immediate failure. Quality EPDM rubber withstands temperature extremes from -40°F to 200°F. However, extreme conditions may require more frequent seal replacement and enhanced conditioning to maintain flexibility and weather protection.